Introduction

In LED display technology, lamp bead technology plays a vital role. COB, SMD, and GOB are three common lamp bead processes. Each process has its own unique characteristics and applicable scenarios. So, which process is better? Let’s have a PK competition for lamp bead craftsmanship to find out!

Session 1: Introduction to LED modules of COB, SMD, and GOB

1). COB process:

The COB process is the abbreviation of “Chip On Board.” Simply put, it is a technology that places a chip without a casing (bare chip) directly on a printed circuit board (which is what we usually call an electronic board). After placing it, you need to connect the circuits (leads) on the chip to the circuits on the circuit board. This process is called “wire bonding”. Finally, a special glue (organic glue) is used to seal the chips and circuits, which protects them from injury and allows them to work together more stably.

This process is like putting a small electronic heart (chip) on a body made of a circuit board, then connecting its blood vessels (leads), and finally putting a layer of protective clothing (organic glue) on it. It works better.

1.1). Advantage:

Smaller point spacing: Because COB packaging technology changes the arrangement and composition of LED lamp beads, smaller point spacing can be achieved. This means that higher-resolution LED displays can be manufactured with resolutions that can almost reach the level of liquid crystals.

Better protective performance: Since the LED chip is directly packaged in the concave light trough of the PCB board and fixed with epoxy resin, the entire light ball forms a convex spherical surface, which makes the product stronger, impact-resistant, and wear-resistant. , greatly improving the protective performance of the product.

Longer life and low dead light rate: COB products encapsulate the LED chip on the PCB board and quickly transfer the heat through the copper foil on the PCB board, reducing the possibility of light attenuation, thus greatly extending the use of the LED display life, and reduces the dead light rate.

Small size and lightweight: Using COB packaging technology, the chip can be packaged in a very small volume, achieving an ultra-miniature design. At the same time, no additional shell or bracket is required, making the overall product lighter and easier to transport and install.

Strong heat dissipation capability: Since the LED chip is directly packaged on the PCB board, the heat dissipation effect is better, thereby improving the stability and reliability of the product.

Excellent all-weather characteristics: COB products adopt triple protection treatment and have excellent waterproof, moisture-proof, anti-corrosion, dustproof, anti-static, anti-oxidation, and anti-ultraviolet properties, and can normally work in various harsh environments.

1.2). Shortcoming:

Higher cost: Although COB technology can reduce production costs in some aspects, the overall cost may still be higher due to the complexity of its production process.

High maintenance costs: because its process requirements are very high, the maintenance cost of COB is also very high. Once a fault occurs, in most cases, it needs to be sent back to the factory for repair.

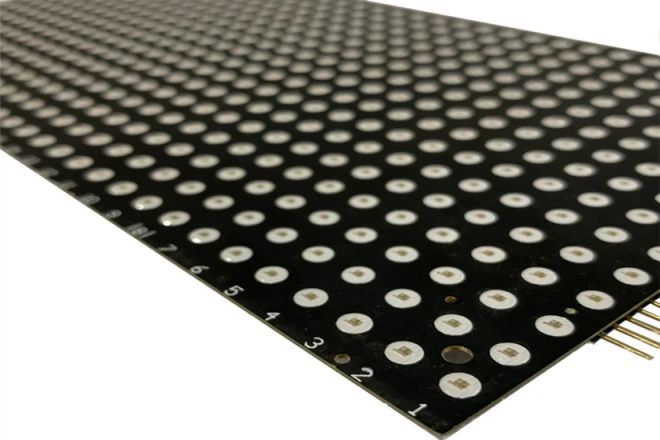

2). SMD process

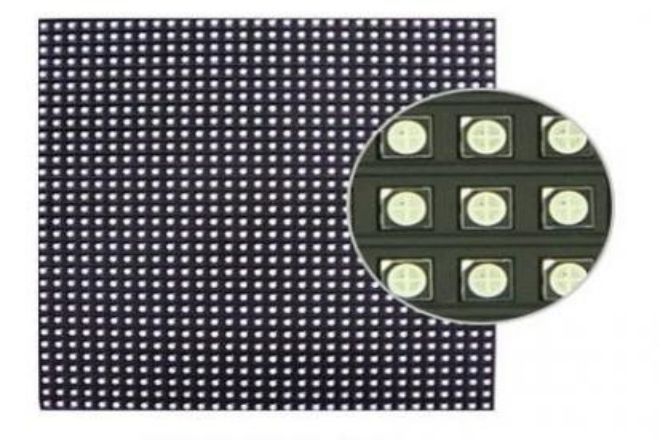

It refers to the process of manufacturing LED modules using Surface Mounted Device (SMD) technology. In this process, small parts such as LED lamp beads, resistors, and capacitors are placed precisely on the printed circuit board. Then, these small parts are firmly fixed on the circuit board through welding and other methods to form a complete LED module.

2.1). Advantage:

High integration and miniaturization: The SMD process makes LED modules more compact and takes up less space. For buyers, this means that these modules can be applied more flexibly, especially in space-constrained environments.

Energy saving and environmental protection: LED modules produced by the SMD process are usually more energy-saving, meet modern green and low-carbon consumer needs, and help reduce energy consumption and environmental pollution.

High brightness and uniformity: The SMD process makes the LED chip layout more uniform, improves the uniformity of light output, makes the light emitted by the module softer and more uniform, and improves the user experience.

Easy to install and maintain: SMD process modules are usually designed with standardized interfaces and connection methods, making installation and maintenance easier and faster.

2.2). Shortcoming:

Low protection level: lamps often do not light up, light up, die, or fall off. In humid climates, large batches of dead or broken lights are prone to occur. It is easy for lights to fall out or break during transportation. It is also easily affected by static electricity, causing dead lights.

Protective masks cannot be used in high temperatures: The SMD of the mask has a small spacing. If used in a high-temperature environment, the mask may easily bulge, affecting viewing. After being used for a period of time, the mask cannot be cleaned, causing it to turn white or yellow, which not only looks ugly but also affects viewing.

3). GOB process:

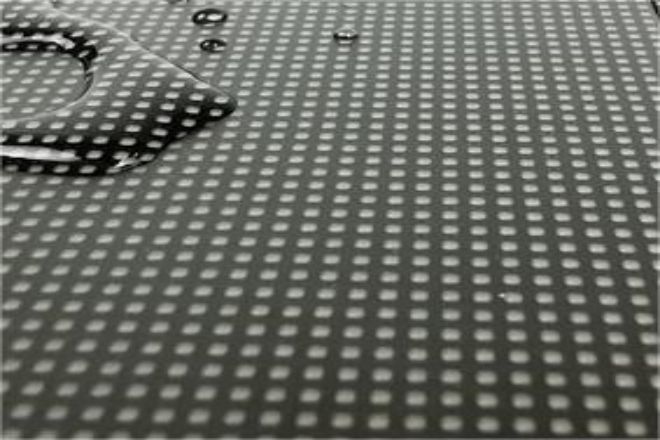

The GOB process is a technology used in LED display manufacturing, and its full name is “Glue On Board.” The main step of this process is to fill the lamp surface of the LED module with special glue. When the glue dries, A strong protective layer is formed on the lamp surface of the module.

This protective layer not only enhances the protective capabilities of the LED display but also has anti-collision, waterproof, dustproof, and shockproof functions.

3.1). Advantage:

High protective performance: The GOB process fills the light surface of the LED module with special glue to form a strong protective layer, thereby significantly enhancing the display’s moisture-proof, waterproof, dustproof, shockproof, and anti-collision capabilities. This allows the display to work normally in various harsh environments, reducing failure rates and maintenance costs.

High display effect: GOB technology realizes the conversion display of the point light source from the surface light source, which significantly improves the display effect of the LED display screen. Buyers can expect clearer, more realistic images, improving their viewing experience.

Long life and low dead light rate: Because the GOB process uses new optical, thermal conductive nano-filling materials and carries out packaging and optical processing through special processes, it effectively reduces the operating temperature and light attenuation of the LED chip, thus extending the service life of the display. And reduced the dead light rate.

3.2). Shortcoming:

Higher cost: Because the GOB process involves special glue filling and optical processing steps and requires the use of high-precision equipment and materials, manufacturing costs are usually higher. This could result in buyers paying a higher price.

Technology maturity: Although the GOB process has certain advantages in LED display manufacturing, its technology maturity may not be as good as the traditional SMD process. This means that buyers may need to bear certain technical risks when purchasing GOB-process LED displays.

High repair and replacement costs: Although the GOB process improves the protective performance and stability of the display screen, the cost of repair and replacement may be higher when a failure occurs.

Session 2: Performance PK

1). performance:

- COB:

Let’s use the food we are most familiar with as an analogy. Imagine that the COB process is like putting a tender steak directly on the grill pan and grilling it. There is no need for cumbersome skewering steps, and the original flavor and delicious taste of the meat are maintained. This is the charm of the COB process.

It directly binds the chip to the PCB board without wire bonding, just like a steak without extra seasoning, making the product performance more reliable and stable. At the same time, since the PCB can be bonded and mounted on both sides, just like a steak can be grilled on both sides, the size of the application module is reduced, providing more space for other components.

- SMD:

The SMD process is like carefully crafted sushi. The LED chip is like fresh fish, fixed on the sushi rice (that is, on the pad of the lamp bead holder) with conductive glue and insulating glue, and then carefully spliced and assembled. Although the production process is relatively long and the cost is high, the final sushi tastes delicious and is of high quality.

Just like the lamp beads produced by the SMD process, the quality is very high.

- GOB:

The GOB process is like putting a layer of “bulletproof vest” on the LED display. Filling the module lamp surface with special glue is like putting a layer of strong armor on the display screen, enhancing its protective capabilities.

At the same time, the use of new optical, thermal conductive nano-filling materials is like adding a pair of “magic eyes” to the display screen, turning the point light source into an area light source, and the display effect is even better.

2). Integration:

In terms of integration, the COB process is like an efficient container. The chip is directly packaged on the PCB board without additional connection pins, just like the various goods inside the container are closely arranged, which improves the integration of the product.

In comparison, SMD technology and GOB technology may be like loading goods in boxes. Although they can achieve a certain level of integration, their efficiency may be slightly lower than that of containers.

3). Cost:

In terms of cost, the COB process is like an affordable cafeteria. The chip is directly bound to the PCB board without the need for cumbersome ball planting, welding, and other steps. It is like picking up food directly in a cafeteria without paying extra.

Therefore, Lower cost. The SMD process is more like a high-end restaurant, requiring more chefs and waiters to make and serve, so the cost is higher. Although the GOB process simplifies some production steps, due to the use of special materials and glue-filling processes, it is like adding special dishes to a restaurant.

Although the taste is better, it may also lead to increased costs.

Session 3: Competition of practical application scenarios

These three processes are all process technologies specifically designed for LED lamp beads, so their application scenarios are highly similar. Thanks to the exquisite skills of these processes, LED displays can be widely used on various occasions. For example, they can be used in the following scenarios:

- Commercial advertising:

LED displays have become leaders in the field of commercial advertising due to their high brightness, high contrast, and excellent color reproduction capabilities. Whether it is a large outdoor billboard, a guide system in a shopping mall, or a promotional information display at the entrance of a store, LED displays can attract people’s attention with their distinctive visual effects.

- Sports events and entertainment activities:

Large-scale sports events and entertainment activities usually require high-brightness and high-definition display equipment to ensure that audiences can clearly see the details of the game or performance.

LED display screens have become the first choice for these occasions because of their excellent display effects and stability.

- Public information and traffic instructions:

In public places such as airports, train stations, subway stations, etc., LED displays are widely used for information release and traffic instructions. They can display flight information, train schedules, bus arrival times, etc., in real-time to provide convenience for people traveling.

- Art and Creative Displays:

The flexibility and customizability of LED displays make them ideal for art and creative displays. Artists and creators can present unique visual effects through LED displays, bringing a new artistic experience to the audience.

- …

Session 4: How to choose COB, SMD, and GOB LED modules

When choosing COB, SMD, and GOB LED modules for LED displays, you need to consider the following factors:

- Display effect:

LED modules with different packaging processes will have different display effects. Generally speaking, COB and GOB-packaged LED displays perform better in terms of color reproduction, contrast, and viewing angles, while SMD-packaged displays may be slightly inferior in these aspects. Therefore, if you have higher requirements for display effects, you can consider choosing COB or GOB-packaged LED modules.

- Stability:

The stability of the LED display is very important for long-term use. In this regard, the GOB packaging process has advantages because it adds a glue-filling process on the screen surface, making the LED lamp beads more stable and reducing the possibility of lamp failure.

Therefore, if you want to buy a more stable LED display, you can choose GOB-packaged LED modules.

- Cost:

LED modules with different packaging processes will also have different costs. Generally speaking, the cost of SMD-packaged LED displays is lower, while the cost of COB and GOB-packaged displays is higher.

Therefore, when purchasing an LED display screen, you need to choose the appropriate packaging process according to your budget.

- Application scenarios:

Different application scenarios may require different packaging processes. For example, if the LED display needs to be subject to frequent impacts or vibrations, it may be more appropriate to choose a COB or GOB package with better protection.

And if the display screen is mainly used for indoor static display, then SMD packaging may be able to meet the demand.

Conclusion

The LED displays supported by these three LED lamp bead processes are very popular because of their diverse application scenarios. Whether in the fields of business, sports, transportation, or art, they can bring convenience and beauty to people’s lives. You can also choose according to your own needs when purchasing.

If you want to know more information about LED displays, please get in touch with us!