Quality control of LED screen

Are you worried about the quality of the LED display before paying the balance?

Do you want to know the complete LED screen quality control process and details?

1. As a professional LED display manufacturer, Bibi Led has a complete and strict quality control process.

2. Bibi Led will work on a strict quality inspection for every step of LED display production.

3. Bibi Led will provide pictures and videos of LED display quality inspection and a quality inspection checking list.

Before the process of production

If there is no detailed plan for the quality inspection of the LED display from the beginning, it is very hard to produce a high-quality LED display.

The quality control of LED display screens should be planned before production, the selection of raw materials, the details of the products should be checked with customers, and the specific production requirements should be confirmed with the factory manager.

Quality material starts it all

The final performance of the quality of the LED display depends on the quality of its raw materials. We must confirm the choice of raw materials before production.

Confirm the solution with the customers

After the order is confirmed, the details of the product must be confirmed with the customer several times, including logo, structure, and other details.

Confirm the production details

This is the most important part. When arranging an order with the production manager, it is necessary to list the complete requirements to ensure that it is all by the requirements of the customer's order.

During the LED screen production

Bibi Led has strict production step requirements and a clean production workshop. We will provide training for employees to ensure that they can strictly follow the production requirements in every production step.

Of course, quality inspection in the production process is also very important. At the end of each production step, we will have a quality inspection responsible for ensuring that there is no problem before the next step.

LED lamp baking

If the SMD lamp beads are not baked, there will be many dead lights after application. Therefore, in order to better ensure that the lamp beads can be used normally, they are generally baked before use.

Efficient Plant & Machinery

Bibi Led understands how important the end-quality machine could bring brilliant and most stable led screen products for you.

Experienced workers

Bibi Led believes only the most qualified staff can go that extra mile to meet your expectations of perfection. It is why Bibi Led never stops employing more LED screen experts in the LED display industry.

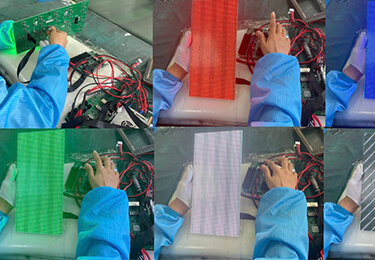

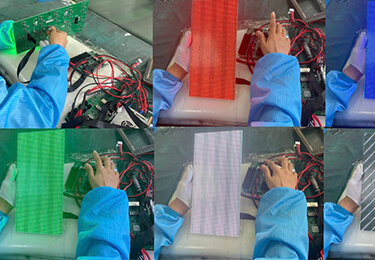

Test for each light up

Bibi Led will inspect each production step, especially for each light up test

LED module aging test

LED module aging test is very important part before assembling the LED cabinet, Bibi Led will do the 12 hours aging test.

Full LED screen aging

When the LED cabinet is assembled, build the entire LED display and conduct an aging test for at least 24 hours.

After finishing the production

When the production of the LED display is completed, we will provide three materials to the customer, quality inspection pictures, quality inspection videos, and quality inspection reports.

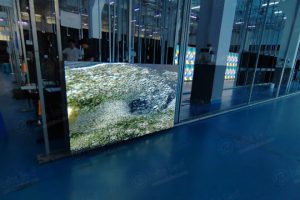

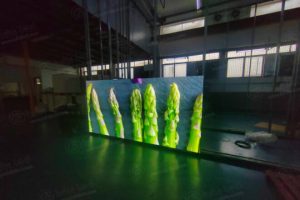

The quality inspection pictures and quality inspection videos will include the production details requested by the customer and the aging effect of the red, green, blue, and white color of the product.

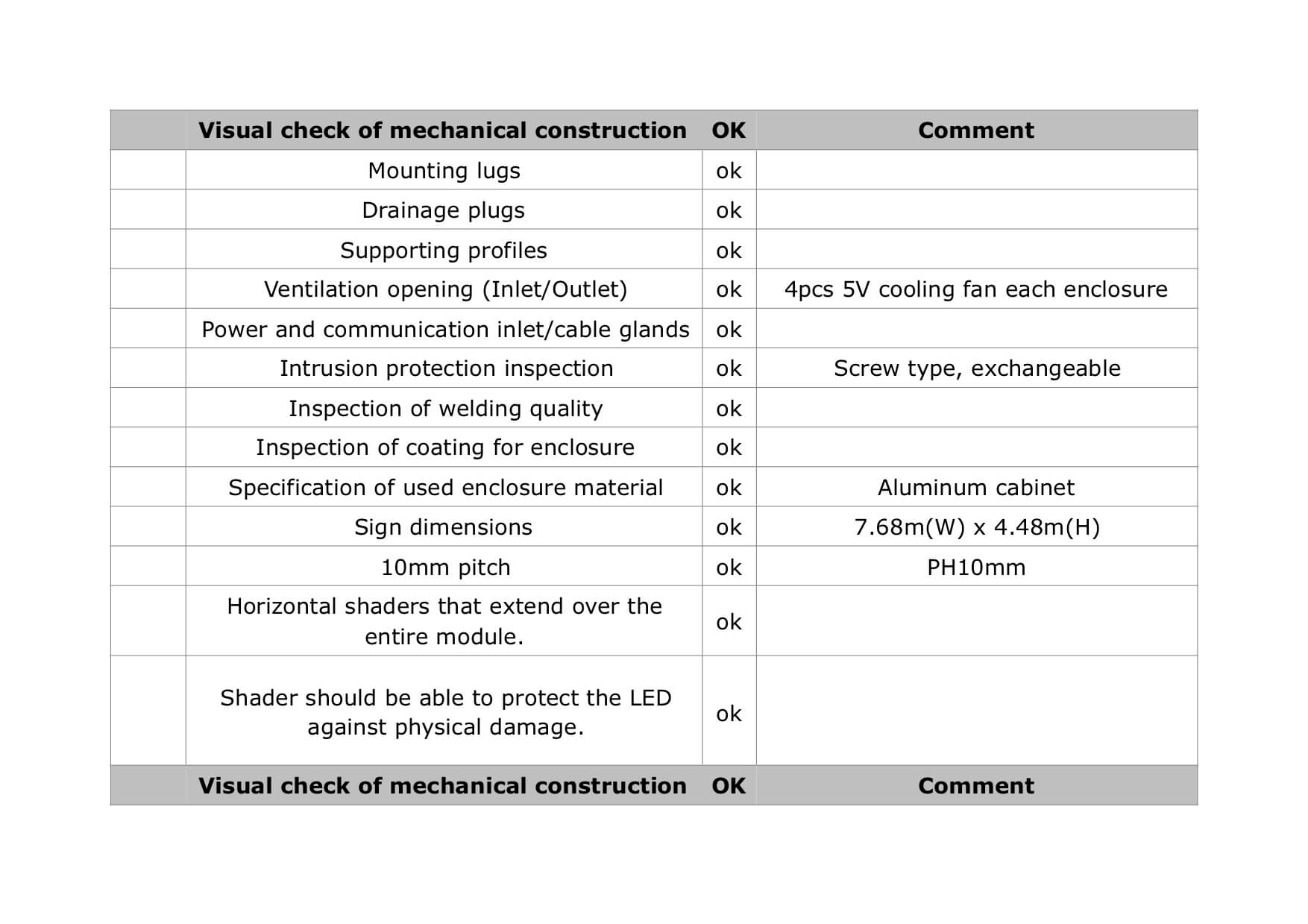

In the quality inspection report, all the quality inspections we have done will be listed in detail, such as quantity, raw materials, size, brightness, waterproof performance test, etc., and the detailed steps of each quality inspection.

Before the LED display is packaged, Bibi Led will ensure that there are no dead pixels, consistent colors, and meet international quality standards for LED displays.

Check the quality inspection videos and pictures as below

For each order, Bibi Led will take care very strictly of quality inspection to make sure our customers are fully satisfied and to build a long-term cooperation.

BIBILED’s P1.25 Indoor LED Display Has Been Shipped To Saudi Arabia

BIBILED’s P1.25 Indoor Front-Maintained LED Display Has Been Shipped To Saudi Arabia

BIBILED’s P1.25 Indoor GOB LED Display Has Been Shipped To Saudi Arabia

BIBILED’s P2.5 Poster LED Display Has Been Shipped To The UK

BIBILED’s P1.25 Indoor LED Display Has Been Shipped To The UK

BIBILED’s P1.86 Indoor LED Display Has Been Shipped To The UK

BIBILED’s P6 Outdoor LED Display Has Been Shipped To Australia

BIBILED’s P3.33 Outdoor LED Display Has Been Shipped To Kenya