The design of LED screens has become more artistic and attractive as a result of the ongoing advancements in LED screen technology. In recent years, LED screens in “wavy,” “spherical,” and other forms have become widespread.

In fact, LED soft modules are used to construct these LED-shaped screens. LED flexible panels are currently in high demand on the market.

So, what is a soft LED module? Let’s learn more about it today.

What is an LED soft module?

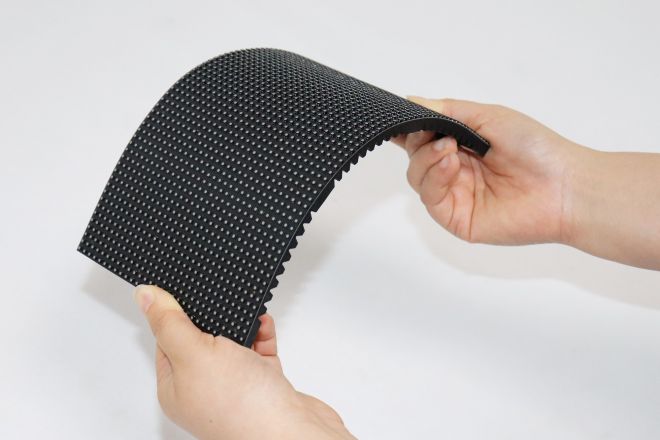

The LED soft module is a new technology of LED display, which uses flexible materials to manufacture LED display panels that can be bent, folded, and in other shapes. Examples include LED curved screens, cylindrical displays, or other unconventional shapes not possible with traditional rigid LED panels.

These modules are usually composed of an LED matrix embedded in a flexible substrate, allowing them to fit on curved or irregular surfaces, and are generally used indoors. Compared with conventional indoor LED screen modules, the biggest advantage of LED soft modules is that they are very flexible and can be bent to 120°.

LED soft modules are flexible, so they can be used in creative displays and often provide high-resolution and vivid visual output while being able to adapt to different environments due to their bendable properties.

The main differences from the manufacturing process

1. PCB distinction

- The traditional indoor LED display uses a hard PCB design, which cannot be bent and is easily damaged.

- LED soft modules are made of flexible PCB that can bend radians less than 120°.

- Flexible FPC circuit board with high compressive and torsional resistance made of flexible insulating material. It can solve the problem of LED displays installed in irregular corners and locations. This is a requirement for ensuring the soft characteristics of the LED soft module, as well as the soft characteristics of the LED soft screen.

2. Bottom shell mask

The conventional indoor full-color screen uses a hard board bottom shell, which cannot be bent at all. The LED soft module uses a flexible shell, which ensures that its soft properties are not limited by the shell.

3. Magnet

The use of a strong magnetic adsorption design ensures that the LED soft module makes a variety of curved panels in the joint smaller. Easy to install and shape, but also quick. The magnets are several times more magnetic than standard indoor LED display modules, resulting in greater adsorption. Magnetic suction installation is as easy as traditional indoor screen installation. The quick joint is used on the connecting line between the module and the module.

In terms of function:

- Because of its ductility, it can be used for arbitrary modeling. Among them, the cylindrical screen can be hoisted, mounted, and so on to meet the site’s requirements to the greatest extent possible. It uses advanced digital video processing.

- Distributed scanning technology, a 360-degree HD display, a modular design, and high color saturation are all features.

- A sharp image with no jitter.

- The screen can be displayed on multiple large ring LED screens at the same time by connecting to the main control computer. The viewer can enjoy several identical images from any angle on the screen.

- Real-time live broadcasting employs DVI, HDMI, 3G/HD/SD three-speed SDI high-definition display mode, which is appropriate for indoor applications such as TV video programs, VCD or DVD, and live broadcasting locations.

In terms of quality:

- High quality, single-point maintenance, and lower cost.

- High brightness, low death rate, energy saving.

- Seamless stitching, the stitching error between modules is controlled within plus or minus 0.1mm, and customers can customize the screen shape according to their needs.

- High flatness and softness.

So, where can LED soft modules be used?

Generally, shopping malls have many pillars. The columns are designed as displays for special videos for decoration or ambiance. This isn’t easy to achieve with traditional screens, but LED soft modules are an ideal choice.

LED soft modules can be used in curved or irregular displays to achieve creative and eye-catching advertising or brand promotion. They can wrap around columns, blend into product displays, or form unconventional shapes to draw attention and attract customers effectively.

- Event and stage design:

The flexibility of LED soft modules is extremely advantageous in event settings. They can be used to create curved or cylindrical screens for concerts, festivals, or corporate events, providing dynamic visuals that enhance the overall attendee experience.

Their versatility allows for innovative stage designs, providing a canvas for creative expression.

There are many LED soft film groups used in airport terminals, such as LED flexible screens composed of soft modules. The airport is equivalent to a showcase for the city, and LED flexible screens can enhance the aesthetics of the space, making it visually attractive and unique.

In addition, the fascinating visual effects of flexible LED screens can effectively attract attention and attract the audience, whether it is advertising, events, or art displays. This also diverts the attention and relieves the emotions of passengers who are anxious because their flight is delayed.

- …

In short, LED soft modules are suitable for occasions that require a certain degree of flexibility and plasticity. They can produce displays of various shapes and sizes, are suitable for various application scenarios, and have broad application prospects.

Conclusion

LED soft modules are widely used due to their soft and flexible properties. The LED soft screen is a popular product right now, and BIBILED product models are available for purchase. We will provide you with full display system solutions.