Introduction

When you purchase an LED display, in addition to receiving the LED display, you will also receive many spare modules. These spare modules are to prevent equipment replacement when the LED display is damaged.

So, how should you store the spare LED display properly after receiving it? Read the article, and you will get the answer.

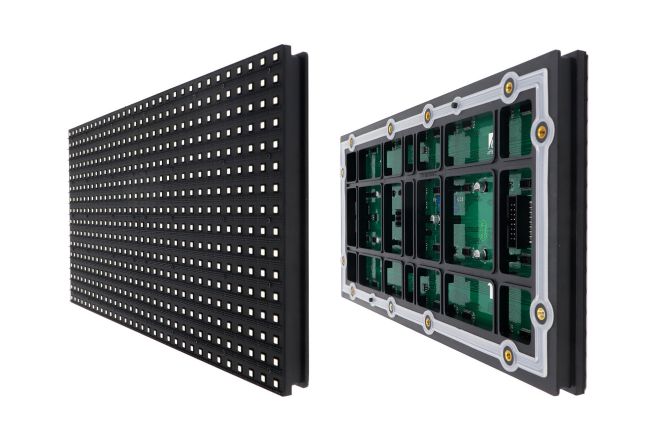

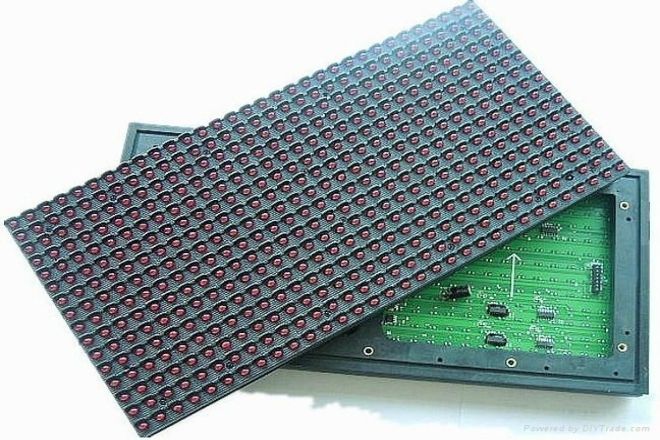

1. Basic knowledge of modules

The LED display module is the basic unit that constitutes the LED display. It is mainly composed of LED lamp beads, drive circuits, connecting lines, and other parts. The quality of the module directly affects the quality and display effect of the entire LED display.

Basic knowledge of LED display modules includes the following aspects:

Pixel: The smallest imaging unit of an LED display screen. It consists of three LED lamp beads: red, green, and blue. By adjusting the brightness of the three lamp beads, any color can be displayed.

Resolution: Indicates the total number of pixels, usually written in the form of width × height, such as 800*600. The higher the resolution, the clearer the display.

Point spacing: The center distance of adjacent pixels. The smaller the point spacing, the shorter the viewing distance and the higher the resolution.

Driving mode: There are two common types: constant current drive and constant voltage drive. The constant current drive has the advantages of good stability and high brightness, so it is widely used in LED displays.

Spare modules refer to modules prepared in LED display systems in case certain modules are damaged or need to be replaced. The spare module usually has the same specifications and parameters as the module in use to ensure that it can be replaced perfectly when replacement is needed and to ensure the normal operation and display effect of the LED display.

Storage of spare modules also requires attention to environmental conditions and management practices to ensure they are in good condition and ready for use.

2. Choice of storage environment

The storage environment of spare modules is critical to ensuring their long-term stability, reliability, and service life. The following are some recommended points for selecting a storage environment:

1). Temperature and Humidity Control

Constant temperature environment: Choose a place where the temperature is relatively stable, and the range of changes is small to avoid deformation or performance changes of the module due to temperature fluctuations. Ideally, the indoor temperature should be controlled between 20-25℃.

Humidity control: Maintain a relatively constant humidity level between 40% and 60% to prevent the module from getting damp or over-drying. Too high humidity may cause a short circuit in the module’s internal circuit, while too low humidity may cause static electricity accumulation. Depending on the indoor humidity, a dehumidifier or humidifier can be installed to adjust the indoor humidity.

2). Dustproof and clean

Dust-free environment: Choose a dust-free or less dusty place because dust may adhere to the surface of the module or enter the interior, affecting its performance. A dust cover can be used to cover the module to reduce dust accumulation further.

Regular cleaning: Clean stored modules regularly to remove surface dust and dirt.

3). Fire protection and safety

Keep away from sources of ignition: Make sure the storage location is away from sources of ignition, flammable items, and chemicals to prevent the risk of fire.

Safety facilities: Install necessary fire-fighting facilities, such as fire extinguishers, smoke alarms, etc.

4). Light and UV protection

Avoid direct sunlight: Ultraviolet rays in sunlight may cause damage to module materials, so direct sunlight should be avoided on the module.

Use blackout materials: If possible, use blackout materials or curtains to block sunlight.

5). Physical Security

Anti-theft measures: Take necessary security measures, such as installing surveillance cameras, access control systems, etc., to prevent modules from being stolen.

Seismic design: If the storage location is located in an active seismic area, seismic design should be considered to ensure that the module will not be damaged during an earthquake.

6). Ventilation and airflow

Good ventilation: Make sure the storage location has good ventilation to prevent the module from overheating.

Avoid direct airflow: Avoid direct exposure of the module to strong air conditioning airflow or fan blowing to prevent damage.

3. Comparison of the advantages and disadvantages of vertical storage versus horizontal storage

1). vertical storage

Vertical storage is a storage method that arranges the spare parts of the LED display vertically.

1.1). Advantage:

Space Utilization: Vertical storage can effectively utilize vertical space, especially on high floors or in places with limited space. This storage method can store more items in a limited space.

Labeling and Identification: The location of each item is clearly visible vertically for easy inventory management and quick identification. This helps improve work efficiency and accuracy.

1.2). Shortcoming:

Inconvenient access: Vertically stored items usually require the use of special tools or ladders, which increases the difficulty and workload of operation.

Stability issues: Items may deform due to gravity, especially heavier items. In addition, if the stability of the shelves or storage racks is insufficient, items may fall or be damaged.

2). Store horizontally

Horizontal storage is a storage method in which LED display spare modules are placed flat on the ground or on shelves.

2.1). Advantage:

Good stability: items stored horizontally are evenly stressed and not easily deformed. This storage method is more suitable for heavier items.

Easy to take and place: Items can be taken or placed directly from the shelf, which is easy to operate and does not require the use of special tools or ladders.

2.2). Shortcoming:

Low space utilization: Horizontal storage requires more horizontal space to store items, and the space utilization is relatively low.

Difficulties in labeling and identification: If not stored properly or clearly labeled, items may be confused and difficult to find quickly.

4. How to choose the appropriate storage rack or shelf based on the size and weight of the module

When choosing storage racks or racks, you need to consider the size and weight of your modules to ensure they can be stored safely, stably, and easily accessed. Here are some specific suggestions:

- Determine the module size:

First, you need to measure the exact dimensions of the module, including length, width, and height. These dimensions will determine the size and type of racking or storage required.

- Evaluate Module Weight:

In addition to size, you also need to know the weight of your module. This will determine the required load-bearing capacity of the rack or storage rack. Make sure the load-bearing capacity of the shelf or storage rack is greater than or equal to the weight of the module to prevent accidents.

- Choose the right shelf type:

Choose the right shelf type based on the size and weight of the module. For example, if the module size is larger and the weight is heavier, you may need to choose heavy-duty racking; if the module size is smaller and the weight is lighter, you may choose light-duty racking. In addition, factors such as the material, structure, and usage environment of the shelves need to be considered.

- Consider shelf depth and spacing:

The depth and spacing of shelves are also factors to consider. The depth of the shelf should be sufficient to accommodate the modules, while the spacing needs to be adjusted according to the size and quantity of the modules to ensure that the modules can be placed stably on the shelf.

- Consider the stability and adjustability of the shelves:

The stability and adjustability of the shelves are also very important. The shelf should be stable and reliable, able to withstand the weight and impact of the module. In addition, the height and number of levels of the shelves should be adjustable to accommodate different-sized modules and storage needs.

- Consider safety and convenience:

Finally, there are safety and convenience considerations for racking. Shelves should be equipped with safety facilities, such as guardrails and non-slip feet, to prevent modules from slipping or toppling. At the same time, access to the shelves should also be convenient and quick to improve work efficiency.

5. How to avoid module damage or deformation during storage

To prevent the module from being damaged or deformed during storage, it is necessary to

Choose a suitable storage environment,

Properly place modules,

Avoid bearing weight for a long time,

Pay attention to dust and rust prevention

Regular inspection and maintenance

These measures will help ensure the integrity and stability of the module and extend its service life. If the module is made of metal, you should also pay attention to anti-rust treatment. You can apply anti-rust oil or wrap it with anti-rust paper.

6. Storage life and maintenance

1). Storage period

The storage period of the module is affected by many factors, including storage environment, load conditions, operating temperature, etc. Generally speaking, if the storage environment is dry, clean, and at a suitable temperature, the service life of the module can reach more than 10 years.

If the storage conditions are more favorable, such as placing the module in a well-sealed glass cabinet, its service life may even be as long as 20 years.

2). Maintain

Regular maintenance is recommended to ensure that the module remains in optimal condition during storage.

Cleaning: Clean the module surface and internal components regularly to remove dust, oil, and other impurities. This helps reduce wear and maintain the performance of the module.

Lubrication: Lubricate the moving parts of the module regularly to ensure they can rotate smoothly when needed. This helps reduce friction and wear and extends the life of the module.

Inspection: Regularly inspect each component and structure of the module to ensure its integrity and stability. If any damage or abnormality is found, it should be dealt with promptly to avoid further worsening of the problem.

Conclusion

The above are the storage instructions for LED display spare modules. If you have other questions about LED modules, please get in touch with us!