Introduction

As an important medium in modern advertising, commercial display, and other fields, LED transparent screens have a direct impact on the quality of the display effect and user experience. This article will introduce in detail the quality inspection methods of LED transparent screens to help consumers and buyers accurately judge the quality of LED transparent screens.

1. Observe the display effect

When testing the quality of LED transparent screens, observing the display effect is a crucial step. By playing high-definition videos or pictures, we can intuitively understand the screen’s color performance, detail presentation, and the smoothness of dynamic pictures.

First, observe the screen’s color performance. A high-quality LED transparent screen should be able to accurately present various colors, with bright, full colors and natural transitions. Color accuracy and richness are critical for advertising and commercial displays to capture the audience’s attention and enhance the delivery of the message.

Secondly, the presentation of details is another important observation point. By playing high-definition videos or pictures, we can see the screen’s ability to handle details. A high-quality LED transparent screen should be able to clearly display the details in the image, such as textures, text, etc., so that the audience can get a more realistic and delicate visual experience.

At the same time, the smoothness of dynamic images cannot be ignored. When playing the video, pay attention to the coherence and smoothness of the picture. A high-quality LED transparent screen should be able to display dynamic images smoothly, avoid lagging, jitter, etc., and ensure that the audience can watch comfortably.

In addition to the above observation points, we also need to pay attention to the performance of the screen in different lighting environments. Since LED transparent screens often need to be installed outdoors or in environments with strong light, their light resistance and adaptability are particularly important.

A high-quality LED transparent screen should be able to maintain a stable display effect in various light environments, ensuring good visual effects in various situations.

Finally, check whether the screen displays white uniformly and whether there is any color difference. No color difference is one of the important indicators for judging the quality of LED transparent screens. By observing the uniformity of the screen when displaying white, we can understand whether the brightness and color distribution of the screen are consistent.

If there is an obvious color difference or uneven brightness when the screen displays white, it means there is a problem with its quality and requires further consideration.

2. Check the screen material and workmanship

When evaluating the quality of LED transparent screens, checking their materials and workmanship is a crucial part. This is not only related to the display effect of the screen but also directly affects its service life and stability.

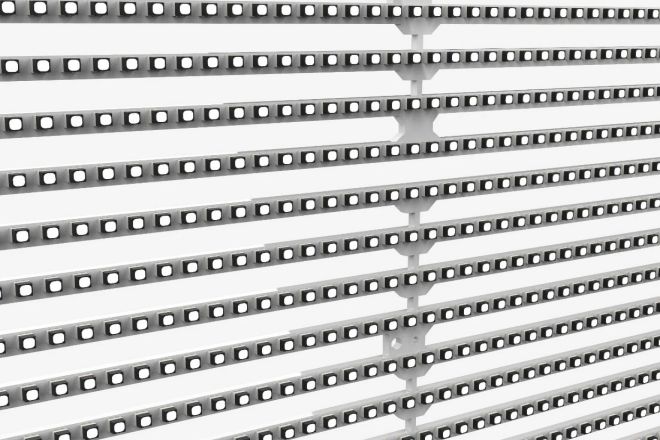

First of all, we need to observe the material selection of the LED transparent screen. As the core component of the screen, the quality of the LED chip directly affects the display effect and service life of the screen.

High-quality LED transparent screens usually use high-quality LED chips, which have the characteristics of high brightness, high color reproduction, and long life. In addition, the selection of conductive materials is also very important. High-quality conductive materials can ensure stable transmission of current and reduce the failure rate.

In addition to LED chips and conductive materials, transparent substrates are also key factors affecting screen quality. High-quality LED transparent screens usually use optical-grade transparent substrates.

This substrate has the characteristics of high light transmittance, low haze, and high flatness, which can ensure that the screen displays clear and delicate pictures while maintaining high transparency.

Next, we need to check the packaging process and splicing technology of the screen. The packaging process is a key step to ensure a stable connection between LED chips, circuit boards, and other components.

High-quality packaging technology can ensure that each LED chip is tightly and stably connected to the circuit board, reducing failures caused by looseness or poor contact. At the same time, splicing technology is also an important factor affecting screen quality.

High-quality splicing technology can ensure that the screens are seamlessly connected during splicing, reducing visual interference caused by gaps while improving the stability and service life of the screen.

When checking the packaging process and splicing technology, we need to pay attention to details such as screen flatness and gap size. High-quality LED transparent screens should remain flat and seamless or have minimal gaps after splicing to ensure that the audience can get the best visual effect when watching.

If there are obvious gaps or unevenness in the screen after splicing, it means that its workmanship needs to be improved.

3. Check solder joint quality

In the quality inspection process of LED transparent screens, the inspection of solder joint quality is a link that cannot be ignored. As the key part connecting the LED chip and the circuit board, the quality of the solder joints is directly related to the stability and reliability of the entire screen.

First, we need to carefully observe the appearance of the solder joints. High-quality solder joints should be plump and rounded, with solder evenly distributed and free of defects such as bubbles and pinholes. Full solder joints mean that the solder is fully melted and tightly combined with the solder joints during the welding process, thereby ensuring stable transmission of current.

Secondly, we need to pay attention to the brightness of the solder joints. Bright solder joints usually mean good solder quality and good electrical conductivity. High-quality solder materials can ensure that the current does not generate excessive heat and resistance during transmission, thereby improving the stability and service life of the screen.

Poor-quality solder joints are prone to poor contact. Poor contact will lead to poor current transmission, causing the LED chip to fail to work properly and even cause the entire screen to malfunction. During long-term use, solder joints with poor contact may further deteriorate due to factors such as vibration and temperature changes, increasing the difficulty and cost of subsequent maintenance.

Therefore, when testing the solder joint quality of LED transparent screens, we need to carefully observe and test each solder joint. Problematic solder joints should be repaired or replaced in time to ensure the stability and reliability of the entire screen. At the same time, we should also pay attention to the selection of welding processes and solder materials to ensure that the quality of solder joints meets standards.

4. Measure the lamp bead temperature

In the quality inspection of LED transparent screens, measuring the temperature of the lamp beads is an important step. The temperature of the lamp bead not only reflects its working status but is also directly related to the stability and service life of the LED transparent screen.

In order to accurately measure the lamp bead temperature, we can use the following method:

Ensure that the LED transparent screen has been lit and has been running stably for a period of time so that the lamp bead can reach a stable working state. Then, gently touch the surface of the LED lamp beads with your hand to feel its temperature. During the touching process, we need to pay attention to the following points:

Make sure your hands are dry and clean to avoid contamination or damage to the lamp beads.

Touch gently to avoid damaging the lamp beads due to excessive force.

Pay attention to safety and avoid electric shock or burns during touching.

By touching the LED lamp beads, we can initially judge its temperature. If the lamp bead temperature is very high or even hot to the touch, it means that its heat dissipation performance is poor, and its stability is correspondingly poor.

LED lamp beads in high-temperature environments will not only reduce their luminous efficiency but also accelerate their aging process, thereby shortening their service life. In addition, excessive temperature may also affect the performance of surrounding components, thereby negatively affecting the display effect of the entire LED transparent screen.

In order to maintain the stability of the LED transparent screen and extend its service life, we need to take a series of measures to reduce the temperature of the lamp beads.

For example, the heat dissipation design of the LED chip can be optimized, and heat dissipation devices such as heat sinks and cooling fans can be added; at the same time, the working time and brightness of the LED transparent screen can be reasonably controlled to avoid overheating of the lamp beads caused by long-term high-brightness operation.

5. Identify wire quality:

In the quality inspection of LED transparent screens, the importance of wire quality cannot be ignored. As a bridge connecting various components, the quality of wires is directly related to the stability, safety, and service life of the entire screen. Therefore, identifying the quality of wires is one of the key steps to ensure the quality of LED transparent screens.

First of all, we should pay attention to whether the wire has passed professional certification. High-quality wire typically undergoes rigorous quality testing and certification processes to ensure it meets relevant standards and specifications.

These certifications may include UL, CE, RoHS, etc., which represent the reliability and compliance of the wire in terms of electrical performance, safety performance, environmental performance, etc.

Secondly, we can directly observe the internal structure of the wire, especially the number of wire cores. The number of wire cores is an important indicator of wire quality. Usually, high-quality wires use more wire cores to carry current and signals to ensure the stability and reliability of transmission.

Therefore, we can directly peel off the outer sheath of the wire and count the number of wire cores inside. Generally speaking, modules using 15, 17, 19 cores, or even 20 or 30 cores, are usually better than modules with 14 or 11 cores in terms of current transmission and signal stability.

In addition to the number of wire cores, we also need to pay attention to the material, diameter, insulation performance, and other indicators of the wire. High-quality wires usually use high-quality conductor materials and insulation materials to ensure the stability and reliability of their conductive and insulating properties.

In addition, the diameter of the wire will also affect its load-bearing capacity and transmission efficiency, so it is necessary to select the appropriate wire specification based on actual needs.

When identifying the quality of wires, we can also use some professional testing tools and equipment, such as resistance testers, insulation resistance testers, etc., to quantitatively detect and evaluate the electrical properties of wires. These tests can help us understand the quality and performance of the wire more accurately, thereby ensuring the stability and reliability of the LED transparent screen.

6. Evaluate permeability

Transparency is an important characteristic of LED transparent screens. It not only determines the screen’s ability to display images while maintaining transparency but also directly affects the visual effects and user experience of LED transparent screens. The LED transparent screen with high transparency can better integrate into the background environment and present a more natural and clear picture.

In order to evaluate the transmittance of LED transparent screens, we can use the following methods:

- Direct observation method:

This is the simplest and most direct method.

We can stand in front of the LED transparent screen and observe the objects or light behind it through the screen. If the objects behind the screen are clearly visible, or light can pass through the screen smoothly, then the screen has a high transparency rate. Although this method is simple, it can intuitively reflect the transparency performance of the screen.

- Quantitative measurement method:

For a more precise evaluation, we can use professional measurement equipment to quantify the screen’s transmittance.

These devices usually measure the light transmittance of the screen, expressed as a percentage. Generally speaking, the higher the transmittance of a screen, the closer its value is to 100%. Although this method requires professional equipment and technical support, it can give more accurate and objective data.

- Comparison method:

We can also compare LED transparent screens with different transmittances together. Under the same conditions, observe how well they transmit objects or light behind them.

Through comparison, we can more intuitively feel the differences between screens with different transmittances. This method is suitable for comparison and selection between multiple samples.

It should be noted that permeability is not the only evaluation criterion. In practical applications, we also need to consider other screen performance indicators, such as brightness, contrast, color reproduction, etc. Only by comprehensively considering these factors can you choose the LED transparent screen that best suits your needs.

In addition, the transmittance is also affected by many factors, such as the selection of screen materials, production technology, installation method, etc.

Therefore, when purchasing and using LED transparent screens, we need to carefully understand their relevant parameters and performance indicators to ensure that they can meet our actual needs.

Conclusion

Through the above 6 aspects of inspection methods, we can comprehensively evaluate the quality of LED transparent screens. When purchasing LED transparent screens, please be sure to pay attention to the above inspection methods to ensure that you purchase high-quality products.

At the same time, it is recommended to choose well-known brands and manufacturers with good reputations to ensure product quality and after-sales service.

Finally, if you want to know more about LED displays, please get in touch with us.