소개

In the classification of LED 디스플레이, in addition to our common distinction between outdoor and indoor, there is also a crucial dimension – that is, the distinction between front maintenance and post-maintenance.

So, do you have a detailed understanding of LED displays for front and rear maintenance? Front-maintenance and post-maintenance LED displays are not only different in maintenance methods but also in design concepts and usage scenarios.

This article will take you into the world of front-maintenance and post-maintenance LED displays and reveal them to you. The mystery.

1. What is a front maintenance LED display?

The front maintenance LED display is a specially designed display that allows maintenance operations such as module replacement, brightness adjustment, heat dissipation cleaning, etc., to be performed from the front of the display without entering from the back or side.

This design makes the front of the display screen more concise and beautiful and, at the same time, facilitates maintenance personnel to perform quick and efficient maintenance operations.

Front maintenance LED displays usually adopt a modular design so that each module can be independently disassembled and replaced. When the module needs to be replaced, maintenance personnel only need to use specific interfaces or tools on the front of the display to complete the removal and installation of the module.

In addition, the heat dissipation design of front-maintenance LED displays is usually more advanced to ensure good heat dissipation under high-intensity use and extend the service life of the display.

Compared with rear-maintenance LED displays, front-maintenance LED displays have the following advantages:

공간 절약:

The front maintenance design does not need to reserve rear maintenance space, allowing the display to be installed more compactly and saving space.

Convenient maintenance:

Frontal maintenance operations are more intuitive and convenient, and maintenance personnel can quickly locate problems and handle them.

High aesthetics:

The front maintenance design makes the appearance of the display screen cleaner and more beautiful, improving the visual effect.

However, front-maintenance LED displays also have certain limitations. For example, in some special installation environments, front maintenance may not be fully achieved.

Therefore, when choosing whether to maintain an LED display before use, it is necessary to comprehensively consider it based on the specific application scenarios and needs.

2. What is a post-maintenance LED display?

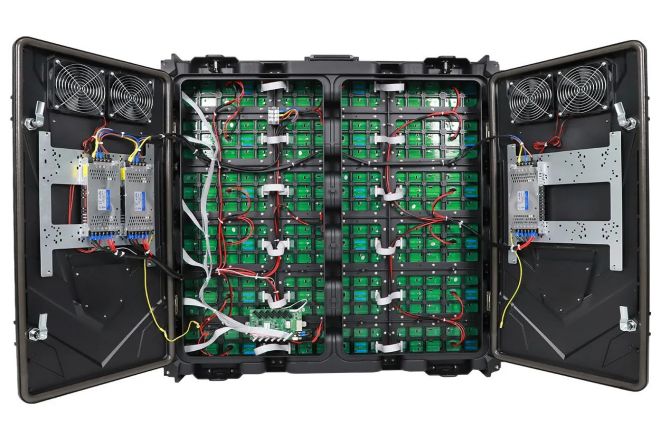

The rear maintenance LED display is a type of display that is maintained and inspected from the back of the box. It is mainly achieved by fixing all the back sides of the LED module to the surface of the box with screws. This design gives the LED display screen good waterproof performance and a stronger structure.

However, since screws need to be driven in from the back of the box, the module cannot be removed from the front after installation. Therefore, sufficient maintenance channels, usually 60~80cm, need to be reserved behind to facilitate later maintenance and inspection work.

Post-maintenance LED displays are mainly suitable for installation scenarios such as roof-type and column-type.

For large LED displays installed on the exterior walls of buildings, the maintenance channels must be designed so that maintenance personnel can perform repairs and inspections from behind the screen, which makes the post-maintenance mode more efficient in these scenarios.

Post-maintenance LED displays have several significant advantages that make them an ideal choice in specific application environments.

The following are the main advantages of post-maintenance LED displays:

- Price advantage:

Compared with front-maintenance LED displays, rear-maintenance LED displays are usually more advantageous in terms of price. This is mainly due to its relatively simple structure and maintenance methods, which reduce production costs.

For customers with a limited budget, post-maintenance LED displays are an affordable option.

- Suitable for large-scale and special installation scenarios:

The post-maintenance LED display is especially suitable for large-scale outdoor installations, such as roof-mounted, column-mounted, etc. In these scenarios, maintenance from the back is not only convenient and efficient but also ensures the stability and safety of the display.

In addition, for large LED displays installed on the exterior walls of buildings, post-maintenance methods can ensure that maintenance personnel can easily enter and operate, improving maintenance convenience.

- Save front space:

Since the maintenance operations of the rear maintenance LED display are mainly performed on the back, its front design can be simpler, and there is no need to reserve additional maintenance space.

This allows the display to better blend into its surroundings, improving the overall aesthetics.

- Maintenance channel design:

After-maintenance LED displays are usually designed with special maintenance channels, which ensures that maintenance personnel have enough space to operate when performing maintenance work.

This design not only improves maintenance efficiency but also reduces operation difficulty, making maintenance work easier.

However, there are also some limitations to post-maintenance LED displays. For indoor recessed or wall-mounted structures, more space may be taken up due to the need for maintenance from the back.

In addition, the need to reserve a maintenance channel on the back may have a certain impact on the aesthetics of the overall design.

3. Front-maintenance and post-maintenance LED displays are suitable for those application scenarios respectively?

Front-maintenance LED displays are mainly suitable for indoor environments or structures that require inlaid or wall-mounted installation. Its design is usually very thin and can blend well with the surrounding architectural environment without appearing obtrusive.

For example, in conference rooms, security monitoring rooms, control and command centers, and other places, we often see front-end LED displays. This is because these places usually have limited space and have high requirements for the aesthetics of the display.

The front maintenance LED display can not only meet these needs but also ensure the convenience of maintenance work.

Of course, there are also some displays installed outdoors that use front maintenance methods. This is mainly due to the pursuit of thinner and lighter LED display cabinets and higher cabinet maintenance efficiency.

Although the outdoor environment is relatively complex, front-end maintenance methods can still ensure the stability and safety of the display through special design and protective measures.

Post-maintenance LED displays are more suitable for places with ample installation space and frequent maintenance.

For example, roof-mounted, column-mounted, and other installation scenarios are typical application places for post-maintenance LED displays. These places usually have larger spaces, and maintenance personnel can easily reach the back of the display for maintenance and repair.

In addition, the price of post-maintenance LED displays is usually relatively affordable, which is one of the reasons why it is favored in some large-scale installation projects.

For outdoor large-scale LED full-color displays installed on building exterior walls, post-maintenance methods are even more indispensable. These displays usually need to be designed with maintenance channels so that maintenance personnel can perform maintenance and inspection from the back of the screen body.

This not only ensures the smooth progress of maintenance work but also ensures the stability and safety of the display.

In addition, some large-area screens used in lecture halls and other places may also adopt post-maintenance designs. This is because, in these places, there is usually enough space behind the screen for maintenance personnel to operate, and the post-maintenance method can ensure the heat dissipation effect of the screen and the convenience of maintenance.

4. How to maintain the LED display screen of front maintenance and rear maintenance respectively?

Front and rear maintenance The maintenance methods of LED displays have their own characteristics, mainly depending on their design structure and installation environment.

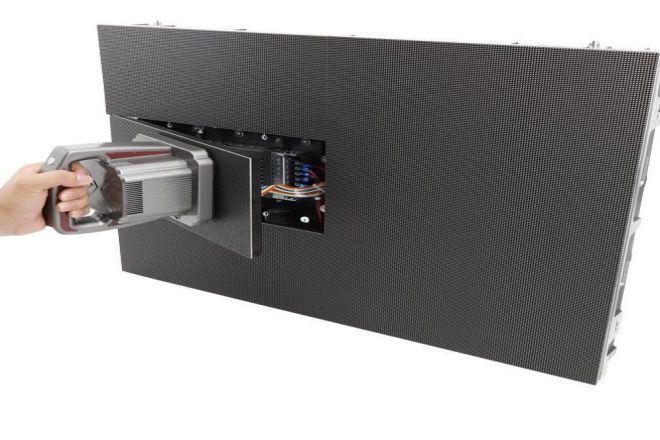

Front maintenance LED display is mainly maintained in the front of the box. A notable feature of this maintenance method is that the LED module is fixed on the box using magnetic components or special designs, making disassembly and installation easier. When maintenance is required, technicians can use specialized tools, such as suction cups, to easily remove the LED modules and perform necessary repairs or replacements.

The advantage of this maintenance method is that it makes the display box lighter and thinner while also improving the efficiency and convenience of maintenance.

Relatively speaking, rear maintenance LED display maintenance is mainly performed behind the box. Since the module and other key components are designed on the back of the box, maintenance needs to be performed from the back.

This maintenance method is particularly common in some large-scale outdoor installations, such as rooftop and column installations. In these cases, sufficient maintenance access is usually reserved so that maintenance personnel can easily reach the back of the display to perform various maintenance operations.

Whether it is pre-maintenance or post-maintenance, regular on-site inspections are essential. This includes checking the operating status of the system to ensure that various components are working properly.

For outdoor displays, special attention needs to be paid to protection against damage from wind, rain, lightning, and other natural factors. Some outdoor displays may be equipped with special protection facilities, such as waterproof boxes or lightning protection devices, to enhance their durability.

In addition, cleaning is also an important part of the maintenance process. Dust and dirt may accumulate on the display surface, which not only affects the display but may also cause damage to the circuitry.

Therefore, regular cleaning with tools such as vacuum cleaners or air guns is necessary. During the cleaning process, avoid using too strong force or tools to avoid damaging the screen.

Finally, for large-scale events and special occasions, on-site guidance and guarantees from technical personnel may be required. This includes ensuring the proper functioning of the display and handling emergencies that may arise.

결론

Choosing the appropriate maintenance method is crucial to the normal operation and stability of the LED display. Therefore, choosing between pre-maintenance and post-maintenance depends on your actual project.

LED 디스플레이에 대해 더 알고 싶다면, 우리에게 연락해주세요.