소개

Are you considering installing an LED 디스플레이, but are you worried about the high maintenance cost? Or your display has been malfunctioning frequently, giving you a headache?

Don’t worry; after reading this article, you may have a new understanding of the maintenance of LED displays!

목차

1. Factors affecting the maintenance cost of LED display

1). 하드웨어 오류

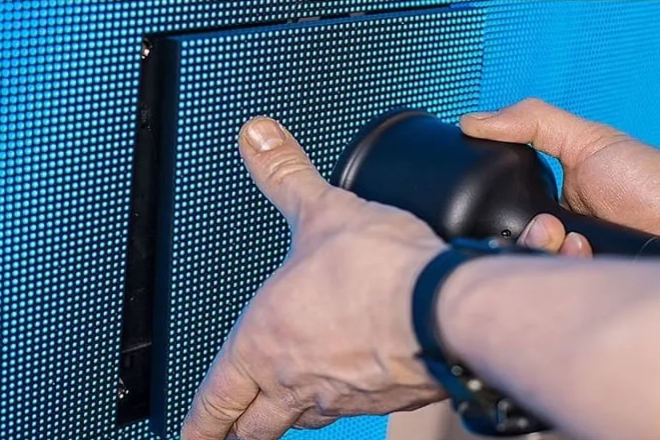

If there is a problem with the hardware of the LED display, the maintenance cost will definitely go up. Let’s talk about LED lamp beads, which are the key components of the display.

If they are in a high 명도 state for a long time, the lamp beads will accelerate aging due to overheating.

If the quality control is not strict during production, the lamp beads may have problems such as cold soldering, and they will break down easily after a short time.

Replacing lamp beads is not cheap. The lamp beads themselves have costs, and you have to ask professionals to replace them. The labor cost is also a considerable expense.

Let’s take a look at the drive circuit, which is also critical.

After long-term work, unstable current and voltage, or excessive ambient temperature, it is easy to damage it.

If the drive circuit is broken, it will be troublesome to repair it. Professional equipment and technicians must be used to repair it.

If it cannot be repaired, a new circuit board may have to be replaced, which will cost more.

Moreover, the machine must be shut down for repair. If the advertising screen stops, the loss is not only the repair fee but also the advertising revenue.

2). Software failure (control system failure)

Software problems are also a headache. If there are loopholes in the control system software of the display, it will be troublesome.

For example, when the software is developed, the code is not written rigorously enough, or some hidden problems are not found during testing, which may easily cause data transmission errors, display abnormalities, etc.

It takes a lot of time and effort to fix these loopholes. The technicians have to check them bit by bit and shut them down for debugging, which costs a lot.

There is also the control card, which is the core hardware of the control system.

If the control card is damaged by static electricity or lightning, the display may be directly “paralyzed.”

Moreover, if the heat dissipation design of the control card is unreasonable, it is easy to overheat and damage during use.

Replacing the control card is not only expensive but also requires reconfiguring the system.

If the wrong or incorrect replacement is made, the display may not work properly, and the loss in the meantime is even greater.

3). Environmental factors

The environment also has a great impact on the LED display. Let’s talk about temperature first. Whether it is too hot or too cold, it is not good.

High temperatures will accelerate the aging of the components in the display, and low temperatures may prevent the components from working properly.

In order to deal with the temperature problem, you may have to install cooling equipment such as fans and air conditioners or insulate the display, which are all additional expenses.

Humidity is also a problem. If the environment is too humid, the components in the display are easily affected by moisture and even short-circuit and corrode.

In humid places, the sealing of the display is not good, and moisture can easily get in.

In order to prevent moisture, you may have to use moisture-proof agents or install dehumidification equipment, which is another expense.

If it is damaged by moisture, it will be troublesome to repair it.

There is also dust. Too much dust will also cause trouble for the display.

Dust accumulation will affect heat dissipation, block the heat dissipation holes, and the display will become hotter and hotter.

If dust runs into the gap, it may also interfere with the work of the components.

Although regular dust cleaning can solve the problem, cleaning itself has costs, and frequent cleaning may damage the surface of the display screen, reducing its service life, which indirectly increases the maintenance cost.

In short, problems in hardware, software, and environment will increase the maintenance cost of LED display screens.

If you want to spend less money, you have to pay more attention to these aspects and try to reduce the occurrence of failures.

2. Common failures and maintenance costs of LED display screens

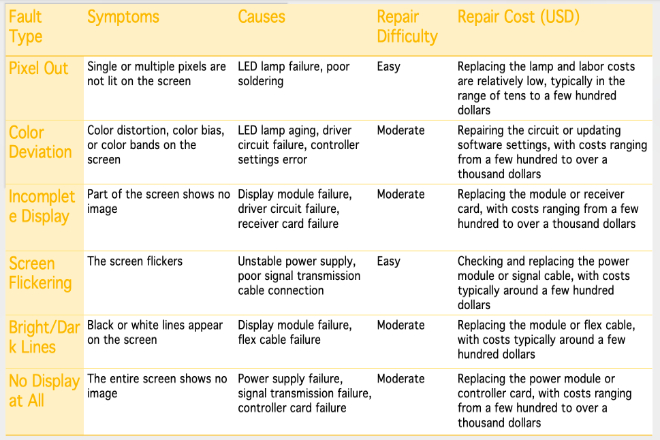

Sometimes, some black spots will appear on the LED display screen; that is, the pixels are not bright.

This is mostly because the lamp beads are broken or there is a problem with the welding.

It is not difficult to repair it. It mainly involves replacing the broken lamp beads. Although the lamp beads themselves are not expensive, it may cost a lot to find a professional to replace them.

In general, it costs tens to hundreds of dollars to repair this fault, depending on the quality of the lamp beads and the repairman’s charges.

If the color of the display screen looks wrong, such as color deviation or color blocks, it may be that the lamp beads are aging, there is a problem with the circuit, or the control card is set incorrectly.

This kind of fault is a bit troublesome to repair, and you have to check the circuit or adjust the settings of the control card. If you just adjust the settings, it may not cost money.

But if you need to replace the circuit board or control card, it may cost hundreds to thousands of dollars, depending on where the problem is.

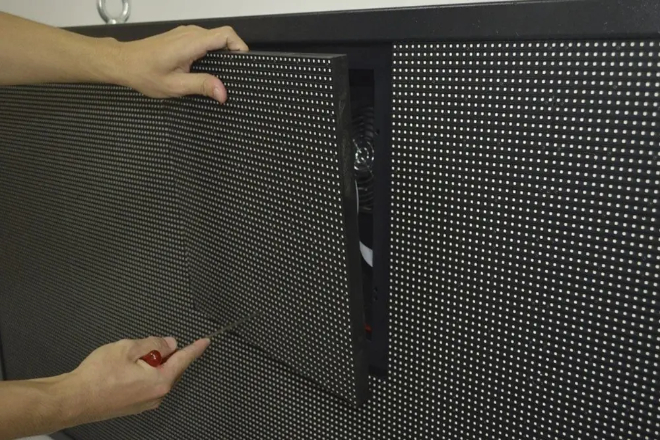

If a part of the display screen does not display anything, it may be that the module, circuit, or receiving card is broken.

This kind of fault is relatively difficult to repair, and the broken parts must be replaced.

It costs hundreds to thousands of dollars to replace the module or receiving card, and the specific price depends on the brand of the component and the repairman’s charge.

If the problem is more complicated, it may take some time to debug, which will also increase some costs.

The screen flickers mostly because of an unstable power supply or poor contact with the signal line.

This problem is relatively simple to repair. Just replace the power module or signal line.

Replacing these parts will cost a few hundred dollars, which is a reasonable price.

This kind of fault is not complicated to repair, so the overall cost will not be too high.

If black or white lines appear on the screen, it may be that the module or cable is broken. The difficulty of repairing this fault is medium, mainly to replace the broken parts.

Replacing the module or cable will cost a few hundred dollars, and the specific price depends on the brand of the component and the repair technician’s fee.

This kind of fault is relatively straightforward to repair; just find the broken part and replace it.

If the entire screen does not display anything, it may be that there is a problem with the power supply, signal transmission, or control card.

This kind of fault is of medium difficulty to repair, and the power supply, signal cable, and control card must be checked.

Replacing the power module or control card will cost a few hundred to a thousand dollars, and the specific price depends on the quality of the component and the repair technician’s fee.

This kind of fault may involve several components, so the repair cost will be relatively high.

3. The importance and cost-effectiveness of preventive maintenance

It is really important to give the LED display a “physical examination” (that is, preventive maintenance) regularly!

Just like people, equipment also needs regular inspections so that small problems can be discovered in advance and prevent them from becoming big problems.

For example, regular cleaning of the display can prevent dust accumulation and hardware damage caused by poor heat dissipation.

Regular inspection of circuits and connecting wires can detect looseness or aging in time to prevent short circuits or signal interruptions.

If this maintenance is not done, small problems will accumulate and may cause the equipment to suddenly “strike,” which is not only troublesome to repair but may also delay important use.

From the perspective of spending money, the investment in preventive maintenance is actually very small, but it can save a lot of money.

Regular cleaning may only cost a few dozen dollars, but if the display has a major failure, such as a broken control card, the repair may cost hundreds or even thousands of dollars.

In addition, the equipment will be down during the maintenance period, and advertising revenue may be lost.

In contrast, although preventive maintenance requires some time and effort, it can greatly reduce the number of equipment failures, and in the long run, it can save a lot of maintenance costs.

In short, preventive maintenance can not only extend the service life of the equipment but also reduce the trouble and losses caused by sudden failures.

Regular cleaning, inspection, and calibration, although it seems a bit troublesome, is definitely cost-effective in the long run.

4. The service life and depreciation cost of LED display

1). How long can LED display be used?

In theory, LED displays can be used for a long time, up to 100,000 hours. If it is used 24 hours a day, it can be used for more than 11 years.

But in actual use, indoor screens can be used for about 6 to 10 years, and outdoor screens can only be used for 5 to 8 years because of wind, sun, and rain.

After all, the outdoor environment is too complicated, and dust, humidity, and temperature changes will make the display “tired.”

2). Why does the life of the display become shorter?

The life of an LED display is affected by many things. For example, the quality of hardware.

If the quality of lamp beads, chips, and power modules is poor, the display will definitely not be used for a long time.

There is also the use environment. If it is too hot, too humid, or too dusty, the display will “retire early.” Heat dissipation is also critical.

If the heat dissipation is not good, the lamp beads are prone to overheating, and the life is short.

There is also the way of use. If you keep the screen on very brightly for a long time or turn it on and off frequently, it will also make the display screen “tired.”

Finally, maintenance is also very important. Regular cleaning circuit inspection and timely repair of problems can make the display screen last longer.

3). How to make the LED display screen last longer?

If you want the LED display screen to last longer, you must first choose hardware of good quality. Don’t be greedy for cheapness. It is more reliable to choose a big brand.

When using it, don’t keep it on very brightly. Just adjust the brightness according to your needs.

Clean the screen regularly and check the circuit to ensure that there is no problem with heat dissipation.

Put the display screen in a well-ventilated and moderately warm place; don’t let it suffer. Be careful when moving and using it; don’t damage it.

4). What is depreciation cost?

Depreciation cost means that the equipment will “depreciate” after being used for a long time.

For LED display screens, depreciation costs account for a lot of the total maintenance cost.

For example, a $10,000 display screen is used for 10 years, and the annual depreciation is $1,000.

However, if it can be used for 15 years through reasonable use and maintenance, the annual depreciation cost will be reduced to $667.

Moreover, regular maintenance can reduce failures and maintenance costs, so the total maintenance cost can be saved a lot.

5. The impact of new technologies on the maintenance cost of LED display screens

In recent years, the technological progress of LED display screens has been great. These new technologies not only make the screen look more beautiful but also help us save a lot of maintenance money.

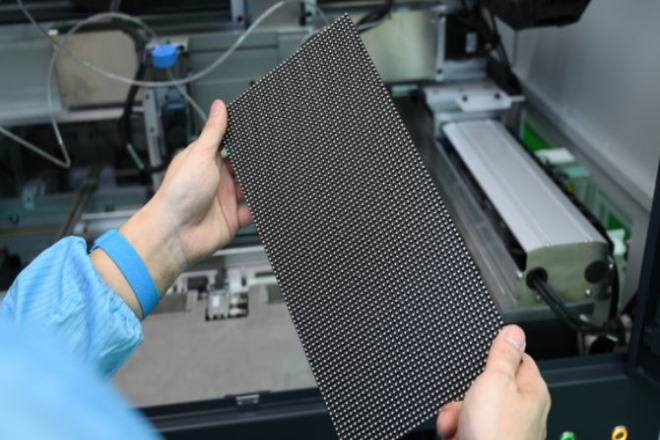

1). Lamp beads are more durable

The previous lamp beads were easy to break after a short time, but now it is different. The new lamp beads are designed to be smarter.

For example, some lamp beads have no substrate, which is not only smaller but also stronger.

These lamp beads are used for a long time and break less, which naturally reduces the number of lamp bead replacements and reduces maintenance costs.

2). Smarter control system

Today’s LED display screens have a smarter “brain” – intelligent control system.

These systems can automatically detect whether the lamp beads are broken, remotely alarm, and even some problems can be solved by themselves.

In this way, we don’t need to go to the site for inspection frequently, saving a lot of manpower and time.

3). Optimized display effects

New technologies make the light extraction and light shaping of the display more powerful.

In simple terms, the screen can emit light more efficiently and can automatically adjust the brightness and color according to the ambient light.

This not only makes the screen look more comfortable but also reduces the trouble caused by frequent adjustments to settings.

6. 결론

After reading this article, do you have a clearer understanding of the maintenance cost of LED displays?

In fact, the maintenance cost is not as high as you think. The key lies in prevention and management.

Through regular preventive maintenance and the use of new technologies, you can not only extend the life of the display but also save a lot of money.

마지막으로 LED 디스플레이에 대해 더 알고 싶으시다면, 저희에게 연락주세요.

다음 내용에 관심이 있으실 수도 있습니다.

Other articles about LED display maintenance: