序章

As an outstanding representative of modern information display technology, LED表示画面 have been widely used in many fields, such as advertising, conferences, and entertainment, due to their excellent brightness, color saturation, and long life.

However, as the use time increases, the LED display screen will inevitably experience light decay, which not only affects its visual effect but may also shorten its service life.

Therefore, an in-depth exploration of the causes and influencing factors of LED display light failure is of great significance for improving its performance and extending its service life.

1. The definition and impact of light attenuation in LED displays

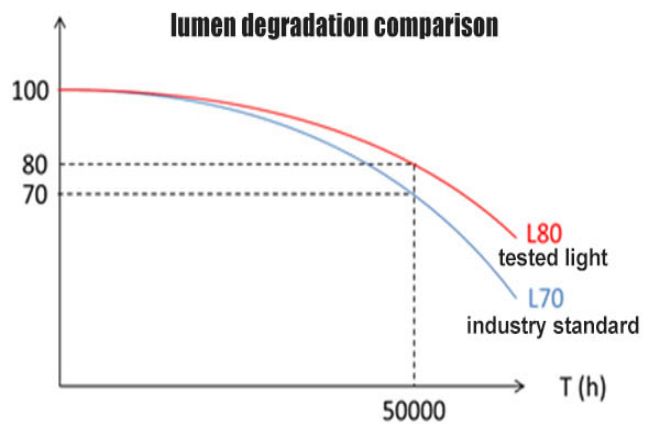

Light decay of an LED display refers to the phenomenon of its luminous intensity gradually decreasing over time during use. This phenomenon does not happen suddenly but is a gradual process. As time goes by, the luminous performance of the LED display gradually weakens.

Specifically, light attenuation manifests itself as a gradual decrease in the brightness of the LED display, weakened color vividness, and reduced contrast. This not only affects the overall visual effect of the display but may also lead to a decrease in user experience during use.

What are the effects of light decay on LED displays:

- Reduced viewing experience:

The phenomenon of light attenuation has a significant impact on the viewing experience of LED displays. As light decay occurs, the brightness of the display gradually decreases, and the originally bright and vivid picture becomes dull. This not only leads to a decrease in the clarity of the picture but also greatly reduces the expression of details, making it impossible for the audience to fully appreciate the wonderful details in the picture.

In application scenarios that require high-quality display effects, such as billboards and theater performances, the impact of light attenuation is particularly prominent. Viewers may be dissatisfied because they cannot see advertising content or performance details, thereby reducing the overall viewing experience.

- Shortened service life:

Light decay is one of the important signs of LED display performance degradation. As light decay intensifies, the luminous performance of the display gradually weakens and cannot meet normal use needs.

This not only shortens the service life of the display but also increases the frequency and cost of replacing the display. For commercial applications, frequent replacement of displays not only affects normal operations but may also have a negative impact on the brand image.

At the same time, light attenuation may also affect the overall operational stability of related equipment and increase the risk of equipment failure.

- Increase in maintenance costs:

In order to slow down the speed of light decay and maintain the good performance of the LED display, maintenance work such as cleaning, repairing, and replacing parts needs to be carried out regularly. This not only adds additional maintenance costs but may also affect the normal operation and efficiency of the equipment.

Regular cleaning work can effectively remove dust and dirt on the surface of the display screen and maintain its cleanliness and light transmittance; maintenance work requires inspection and debugging of the display screen to ensure its normal operation; and component replacement may involve more complex The operation requires professional technical personnel.

These maintenance tasks not only increase operating costs but may also interfere with the normal operation of the equipment.

2. Reasons for LED display light failure

- LEDチップの品質

The LED chip is the core component of the display screen, and its quality is directly related to the light decay speed of the display screen. High-quality LED chips usually have high luminous efficiency and long service life, which can effectively reduce the light decay rate.

On the contrary, poor-quality chips may have unstable luminous performance and accelerated light decay due to material defects or process problems.

Specifically, the difference in chip quality is mainly reflected in the following aspects:

First, the material selection of the chip, such as using high-purity and high-stability materials, can improve the luminous performance of the chip; second, the structural design of the chip, a reasonable structure The design helps reduce heat accumulation and light loss.

Third, the chip manufacturing process, such as precise cutting and packaging, is crucial to ensuring chip performance.

- Packaging materials

Encapsulation materials also play an important role in the light attenuation of LED displays. The main function of the packaging material is to protect the LED chip from the external environment, such as moisture, dust, and mechanical impact.

At the same time, packaging materials also need to have good light transmittance and heat dissipation properties to ensure the luminous efficiency and service life of the LED chip.

High-quality packaging materials usually have high light transmittance and low moisture absorption, which can effectively reduce the loss of light during the packaging process. In addition, good heat dissipation performance helps reduce the heat generated by the LED chip during operation and reduces light decay caused by high temperatures.

- Manufacturing process

The sophistication of the manufacturing process also has an important impact on the light attenuation of the LED display. Advanced manufacturing processes can ensure precise coordination between LED chips and packaging materials, reducing light attenuation caused by process defects.

Specifically, the manufacturing process includes chip cutting, packaging, welding, and other links. In these links, any slight error may cause the performance of the LED display to degrade.

Therefore, using advanced manufacturing equipment and process methods and strictly controlling every production link is the key to reducing the light decay rate of LED displays.

- Working environment and conditions

The light attenuation of LED display screens is closely related to the working environment and conditions in which they are located. Different environmental factors can have a significant impact on the performance of the display, thereby accelerating or slowing down the rate of light decay.

First of all, temperature is one of the key factors affecting the light decay of LED displays. A high-temperature environment will accelerate the movement of electrons inside the display screen, resulting in increased energy loss, thereby exacerbating the light attenuation phenomenon.

After being exposed to high temperatures for a long time, the luminous performance of the LED display will gradually decrease, the brightness will be weakened, and the color will be distorted.

Therefore, reasonable control of the working environment temperature and keeping the display screen within a suitable working temperature range are effective measures to slow down light decay.

Secondly, humidity also has a non-negligible impact on the light attenuation of LED displays. Excessive humidity can easily cause corrosion of the internal components of the display, thereby affecting its luminous performance.

Especially in humid environments, moisture may penetrate into the interior of the display and react chemically with the circuit board and components, causing accelerated light decay.

Therefore, keeping the humidity of the working environment within a reasonable range and preventing the display screen from being wet for a long time are important measures to reduce the risk of light decay.

In addition, dust and pollution are also important factors affecting the light decay of LED displays. Dust and contaminants may adhere to the display surface, blocking light transmission and causing a decrease in brightness.

At the same time, these pollutants may also cause damage to the electronic components inside the display screen, further exacerbating light degradation.

Therefore, regular cleaning and maintenance of LED displays to remove dust and pollutants on the surface is of great significance to maintaining good luminous performance.

- Usage methods and habits

In addition to the working environment and conditions, the usage and habits of LED displays will also have an impact on light attenuation.

First of all, brightness adjustment is one of the important factors affecting light attenuation. Using an LED display at high brightness for a long time will accelerate its light decay.

Excessive brightness will not only increase the energy consumption of the display but also cause discomfort to the viewers’ eyes. Therefore, when using an LED display, the brightness should be appropriately adjusted according to actual needs to avoid long-term high-brightness use.

Secondly, frequent switching of the LED display may also cause its light decay to accelerate. During the switching process, the electronic components inside the display will experience sudden changes in current, which may cause damage to the components and accelerate light decay.

Therefore, in order to reduce the light attenuation phenomenon, unnecessary switching operations should be minimized to maintain the stable operation of the display screen.

Finally, regular cleaning and maintenance of LED displays are also important measures to slow down light decay. During use, dust and dirt may accumulate on the display surface, and these contaminants will affect the transmission of light and the display effect.

Through regular cleaning and maintenance, these contaminants can be removed, maintaining the cleanliness and light transmittance of the display, thereby slowing down the rate of light decay.

To sum up, the working environment and conditions, as well as usage methods and habits, are important factors that affect the light decay of LED displays.

In order to maintain good performance of the display and extend its service life, we should reasonably control the temperature and humidity of the working environment, avoid long-term high-brightness use and frequent switching operations, and clean and maintain it regularly.

3. Measures to slow down the light decay of LED displays

In order to effectively slow down the light decay of LED displays and improve their service life and performance stability, we need to take a series of targeted measures. These measures cover all aspects, from material selection and manufacturing to use and maintenance, aiming to comprehensively improve the quality and use effects of LED displays.

初めに、 the selection of high-quality LED chips and packaging materials is the basis for slowing down light decay. High-quality chips have excellent luminous efficiency and stability and can significantly reduce the speed of light decay.

At the same time, good packaging materials can effectively protect the chip from the external environment and further extend the service life.

Therefore, when purchasing LED displays, we should pay attention to the material and craftsmanship of the product and choose reputable brands and suppliers.

第二に、 optimizing the manufacturing process is also the key to reducing the light attenuation rate.

By introducing advanced production equipment and technology and improving the precision and consistency of the manufacturing process, we can reduce defects and errors in the production process, thereby ensuring the stable performance of the LED display.

加えて、 strengthening quality control and testing to ensure that each factory product meets standard requirements is also an important means to improve product quality.

In addition to material selection and manufacturing measures, we also need to control the temperature and humidity of the working environment strictly. High temperature and high humidity are among the important factors leading to the failure of LED displays to light.

Therefore, when installing and using the display, we should choose an environment with good ventilation and suitable temperature and avoid prolonged exposure to moisture or high temperature.

In addition, when used in special environments, you can consider adding heat dissipation equipment or taking other cooling measures to reduce the impact of temperature on display performance.

Regular cleaning and maintenance of LED displays are equally important. During use, dust, dirt, and other contaminants may accumulate on the surface of the display. These contaminants not only affect the viewing effect but may also accelerate light decay.

Therefore, we should clean the display screen regularly, using a soft cloth or professional cleaner to gently wipe the surface to ensure it is clean and dust-free.

At the same time, it is also necessary to regularly check the working status of the display screen and promptly discover and deal with potential problems to ensure its long-term stable operation.

ついに、 the rational use of LED displays is also an effective way to slow down light decay. During use, we should avoid running the display at high brightness for a long time to reduce the chip loss.

At the same time, unnecessary switching operations should be minimized to avoid damage to the internal components of the display due to frequent current surges.

In addition, adjusting parameters such as brightness and contrast according to actual needs to make the display work within a comfortable range is also an important measure to extend its service life.

結論

Through an in-depth exploration of the light decay phenomenon of LED displays, it is not difficult to find that its light decay speed is closely related to many aspects.

From the selection of LED chips and packaging materials to the optimization of the manufacturing process to the control of the working environment and the development of usage habits, every link has a direct or indirect impact on the light decay speed of the LED display.

If you would like to know more about LED displays, ご連絡ください。