序章

Have you ever encountered this situation: even though it’s the same LED表示, why do some areas appear cooler or warmer in color, and the brightness is uneven?

Or, after splicing screens together, the colors just don’t seem to match? This seemingly small problem can actually affect the display effect and the viewer’s experience.

So, what exactly causes inconsistent colors in LED displays? Today, we will discuss several common reasons to help you better understand how to avoid this problem and ensure consistent screen colors.

目次

1.What constitutes "color inconsistency" in LED displays?

Simply put, color inconsistency in LED displays refers to significant differences in color, 輝度, or color temperature across different areas of the display screen, resulting in an overall unbalanced effect.

This phenomenon can occur in any part of the screen, from localized color shifts and uneven brightness to differences after splicing new and old screens, all affecting the viewing experience.

Common manifestations of color inconsistency:

This is the most common type of color inconsistency. Some areas of the screen may show color deviations.

For example, some areas may appear cooler or warmer than others, or the displayed colors may not be uniform, resulting in a “blotchy” appearance.

This is usually caused by the inconsistent quality of LED lamp beads or imprecise panel manufacturing processes.

Different areas of an LED display may have differences in brightness and color temperature.

Sometimes, some parts of the screen appear brighter or darker than others, making the entire image look unbalanced.

Similarly, differences in color temperature can make some areas appear cooler or warmer, affecting the overall visual effect.

This usually occurs when multiple LED displays are spliced together to form a large screen. Even with the same model of screens, the color differences between new and old screens can be very noticeable.

This is because different batches of LED panels may have slight differences during production, leading to inconsistent color performance between screens.

Reason 1: Differences in the LED lamp beads themselves

The problem of color inconsistency in LED displays is often due to differences in the LED lamp beads.

Even LED lamp beads of the same model may have slight differences from different batches, especially in color, brightness, and color temperature.

These differences may become particularly noticeable after screen splicing or after a period of use, affecting the overall display effect and providing a poor experience for viewers.

The quality of LED lamp beads may vary due to different production batches.

During the production process, raw materials, equipment, and other details can lead to differences in color temperature and brightness between different batches of lamp beads.

This difference is easily noticeable in spliced screens, advertising screens, or scenarios with high color accuracy requirements.

For example, if one part of a screen uses lamp beads with a warmer color temperature, while another part uses cooler lamp beads, the overall display effect will look uneven and may even affect the aesthetics of the image.

In addition, low-cost LED displays often use lamp beads with unstable quality.

These lamp beads may not have strict binning management during the production process, or the quality control is not strict enough, so color difference problems are relatively common.

Manufacturers of low-cost solutions may overlook these details to reduce costs, leading to color difference problems gradually becoming apparent after long-term use.

Although it may seem cheaper initially, in the long run, it may require constant repairs or replacements, which actually increase additional costs.

Reason 2: The influence of driver ICs and control systems

1). The impact of driver ICs on color inconsistency

The driver IC is responsible for providing current to the LED lamp beads; simply put, it determines the 輝度 of each LED lamp bead.

If the quality of the driver IC is poor, or the current it provides is unstable, then the performance of the LED lamp beads will be problematic.

Some areas may become particularly bright, while others are dim, and the color may even deviate, making the entire image look inconsistent.

For example, if the current control of the driver IC is poor, some parts of the screen may appear to have inconsistent colors.

Color difference problems are especially noticeable in spliced screens because the lamp beads of each spliced screen are regulated by the control system, and any subtle current fluctuations will affect the overall display effect.

2). The role of the control system

The control system is like the brain of the display screen; it is responsible for receiving input signals and transmitting them to the driver IC.

If there are problems with the control system’s algorithm or the adjustments are inaccurate, color inconsistency will occur.

The control system also needs to have color correction functions, but if this part is not done well.

The screen may experience problems such as inconsistent color temperature and brightness differences, especially after the screen has been used for a period of time.

The differences will become even more obvious. Additionally, if the control system settings do not properly synchronize the display effects across different areas, it can also lead to color unevenness.

For example, color differences between different modules, if not corrected promptly by the control system, can cause significant deviations in the display effect of certain parts of the screen, affecting the overall viewing experience.

3). Problems that may arise from poor matching between the driver IC and the control system

If the driver IC and the control system are mismatched, it will affect the accuracy of signal transmission and current regulation, leading to color inconsistencies.

This is like two partners; if one doesn’t perform well, the other cannot function effectively either.

Therefore, choosing the right driver IC and control system and ensuring they work together smoothly is crucial to avoiding color inconsistencies.

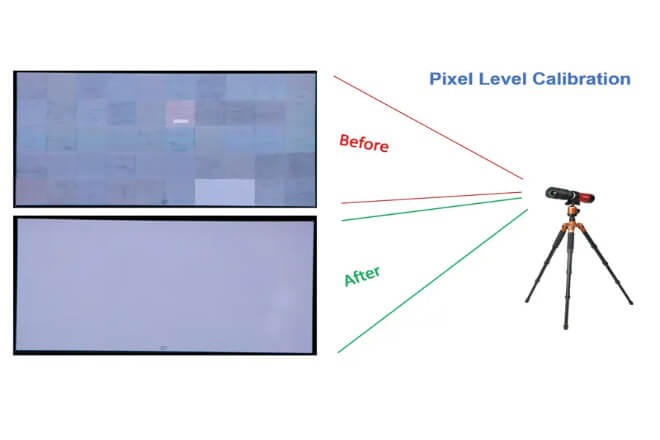

Reason 3: Insufficient calibration and debugging – the most easily overlooked reason

1). Why are calibration and debugging so important?

Calibration is a key step in ensuring accurate and consistent screen colors. I

t involves adjusting the screen’s color temperature, 輝度, contrast, etc., to ensure the overall display effect meets the requirements.

Debugging ensures that all display modules achieve optimal performance in actual use, including adjusting the screen’s brightness uniformity and color temperature matching.

If calibration and debugging are insufficient, the screen’s display effect will be difficult to meet the expected standards.

For example, some areas may be too bright or too dark, or there may be significant color temperature differences between different areas, affecting the overall image quality.

This problem is particularly noticeable in large-screen splicing, where color differences are more easily amplified.

2). Why is this part easily overlooked?

Many people, after installing an LED display screen, may think that the screen’s display effect is “good enough” and do not perform further adjustments and optimizations.

Especially in the initial stages, with simple display content, color difference problems may not be easily detected.

However, with increased usage time, especially with complex images or prolonged display, color differences and inconsistencies will gradually become apparent.

In addition, some display screen manufacturers and installation companies may omit detailed calibration and debugging work due to cost considerations and proceed directly to the usage stage.

While this approach may seem to save time and costs, in the long run, the screen’s color consistency and display effect will be affected.

Reason 4: The impact of installation environment and usage conditions

1). The impact of temperature and humidity

Using LED display screens in high-temperature or high-humidity environments may adversely affect the display effect.

High temperatures accelerate the aging process of LED lamp beads, causing changes in 輝度 and color temperature, leading to color difference problems.

Especially in summer or high-temperature environments, the lifespan of LED lamp beads is shortened, resulting in a gradual decline in the display effect of the screen.

High humidity also affects the performance of LED displays, especially in outdoor environments.

Moist air can enter the display, causing the circuit board to become damp or corrode, which in turn affects the operation of the driver IC, resulting in uneven brightness or inconsistent color temperature.

For screens that are exposed to high temperatures and high humidity for extended periods, color inconsistency problems are particularly noticeable.

2). Influence of Lighting Conditions

Lighting is an important factor affecting the color performance of LED displays, especially in outdoor or brightly lit environments.

If the display is exposed to strong natural light, the screen’s colors may appear lighter or less distinct.

In addition, lighting conditions can also affect the brightness and contrast of the screen, causing the display effect in certain areas to be less than expected.

For example, outdoor advertising screens are usually exposed to strong sunlight, and the screen may display color differences due to light reflection or overexposure.

This problem is usually particularly noticeable during the day, but as the usage time increases, the color differences on the screen become more prominent.

3). Influence of Installation Angle と 視聴距離

The installation angle also affects the viewing effect of the LED display. LED screens usually have an optimal viewing angle, and when viewed from outside this angle, the color, brightness, and contrast of the screen will decrease.

Especially in large-screen splicing, if the installation angles of multiple screens are not uniform, color difference problems are likely to occur.

Therefore, ensuring consistent viewing angles of the screens is very important when installing LED displays.

Viewing distance also affects the color consistency of LED displays. The color and brightness performance of the screen will vary at different viewing distances, especially when the displayed content is complex, and the color difference problem may be amplified.

6. How to Reduce Color Risks in Advance?

Color consistency is one of the key performance indicators of LED displays, especially on occasions requiring high-quality display effects such as advertising, conferences, and exhibitions, where color uniformity is crucial.

To ensure color consistency and reduce color risks, decision-makers can take several steps to ensure that the chosen solution meets the requirements for color consistency.

How to determine whether a solution prioritizes color consistency?

1). Does the supplier have a comprehensive LED binning management system?

LED binning (classification management) is a crucial step in ensuring color consistency.

A professional LED display manufacturer typically performs precise classification of LED chips with different color temperatures and brightness levels to ensure consistent color temperature and brightness across each display screen.

If the supplier can provide LED binning information and detail their sorting standards, it indicates that the solution prioritizes color consistency.

2). Is there a precise calibration process?

The calibration process of LED displays is key to maintaining color consistency.

If the supplier has a mature calibration process that allows for fine-tuning of color temperature, brightness, and color balance for each screen, then this solution can effectively avoid color inconsistency issues.

Decision-makers can request a review of the supplier’s calibration process to ensure it meets industry standards.

3). Does the supplier provide comprehensive after-sales support?

Color consistency is not just a matter of installation; color differences may appear after long-term use.

A supplier who values color consistency should provide strong after-sales support to ensure timely adjustments and repairs when problems arise.

The quality of after-sales support directly impacts the color performance of the display in actual use. Choosing suppliers that offer comprehensive support and long-term guarantees can effectively reduce color risks.

7. 結論

By understanding the major common causes of color inconsistency in LED displays.

We can see that every aspect, from the quality of the LED chips to the stability of the driver ICs, and from the installation environment to post-installation debugging, can affect the display effect.

Although these issues may seem minor, they accumulate and can ultimately seriously affect the audience’s experience and brand image.

Therefore, when purchasing, installing, and using LED displays, paying attention to every detail and ensuring color consistency is essential to maintain optimal display performance.

Finally, if you would like to learn more about LED displays, ご連絡ください。