序章

Have you ever encountered this situation: a space with an unusual shape, wanting to install a screen but unable to find a suitable size?

Or wanting a curved, wave-shaped, or wraparound screen but worried about technical and cost issues? Can LEDディスプレイ really be customised to meet specific installation needs?

The answer is yes, but it’s important to understand the principles, feasibility, and potential risks of customisation.

目次

1. Analysis of Special Installation Needs

In some commercial projects, the installation of LED displays has special requirements, which not only affect screen selection but also directly impact the effect and construction difficulty.

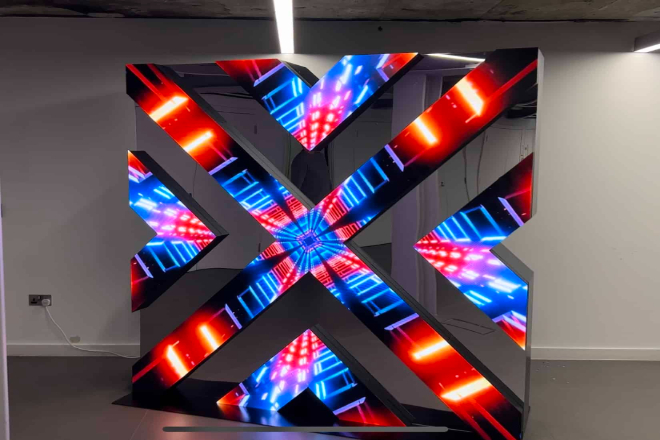

Irregularly shaped LED displays refer to screens with non-rectangular designs such as circles, curves, or waves.

The biggest challenge with these screens is maintaining the integrity and smoothness of the image on the irregular shape.

Irregularly shaped screens are typically used for high-end brand displays, art installations, or immersive spaces, offering a unique visual experience, but installation and debugging are relatively difficult, requiring advanced design planning.

Large-scale spliced LED displays are ultra-wide or ultra-high screens, commonly used in ショッピングモール atriums, 展示会, or advertising.

When selecting this type of screen, the key is to ensure minimal seams, uniform 輝度, and stable image quality.

The larger the screen, the higher the requirements for structural support, heat dissipation, and power supply layout. Without prior planning, uneven brightness or system instability can easily occur.

Partially integrated LED displays mainly refer to space-adaptive installations such as on walls, ceilings, ステージ, and columns.

These screens emphasise seamless integration with the surrounding environment, making the screen appear as part of the space.

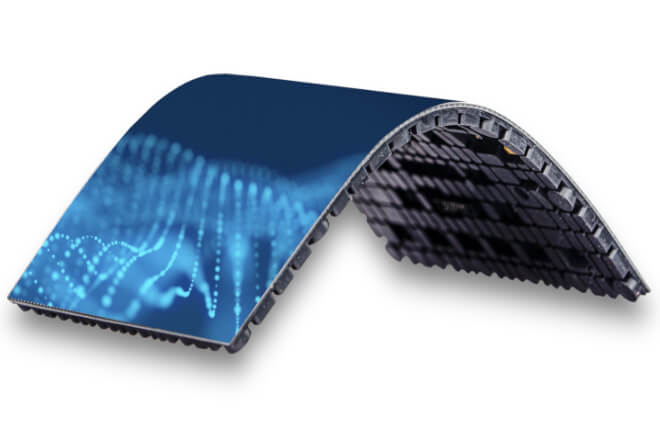

Common methods include bent screens, embedded installations, or custom brackets. Besides visual effects, construction safety and subsequent maintenance are also crucial considerations.

Finally, special installation environments are also a necessary factor in screen selection. Outdoor screens need to be waterproof, dustproof, heat-resistant, and even UV-resistant to ensure stable operation around the clock.

While indoor screens are not affected by wind and rain, prolonged screen operation can generate high temperatures, making heat dissipation and maintenance equally important.

Environmental conditions directly affect screen lifespan and user experience, so a thorough assessment must be conducted before installation.

2. LED Display Technology Feasibility and Design Scheme

1) Modular design makes screens more flexible.

The advantage of modular design is that standard modules can be assembled into various sizes and shapes, easily combining ultra-large rectangular screens, curved screens, and various creatively shaped screens.

Modular design also facilitates later maintenance; if a module fails, only that module needs to be replaced, without disassembling the entire screen.

2) Pay attention to pixels and 解決 for curved and irregularly shaped screens.

When designing curved or irregularly shaped screens, pixel spacing and resolution cannot be used arbitrarily.

When the screen is curved, the image will change slightly; if the pixels are too large, the graininess will be noticeable up close.

If the resolution is too low, details will not be clear enough. The design must balance image clarity and cost, ensuring a comfortable viewing experience from both near and far.

3) 電源, control, and heat dissipation must be considered in advance.

Custom screens are often large or have unique shapes; power distribution, control system load, and heat dissipation issues cannot be ignored.

The power supply and control system must be rationally laid out to ensure stable, lag-free images; good heat dissipation is essential for the screen to operate for extended periods without brightness degradation or malfunction.

4) Case Study Sharing

In a high-end showroom case, the team used modular small-pitch LEDs to create a curved wall.

By adjusting the pixel pitch and control system layout, they not only achieved a stunning visual effect but also ensured the screen’s long-term stable operation.

This example illustrates that creative design and technical feasibility can be balanced, provided the planning is reasonable.

3. Cost and Timeline Considerations for Customised LED Displays

1) Why are Customised Screens More Expensive?

Customised screens are generally more expensive than standard screens, and there are reasons for this.

First, irregularly shaped, curved, or large screens require additional design and processing; modular splicing and special brackets increase costs.

Second, ピクセルピッチ, resolution, and control systems may need to be adjusted for the project, increasing material and labour costs. Simply put, customised screens cost more but achieve effects that ordinary screens cannot.

2) Production Cycle, Transportation, and Installation Impact on Schedule

Customised screens are not only more expensive but also require a longer time to be implemented.

Design, production, testing, transportation, and on-site installation are all more complex than with standard screens.

Especially for large-scale splicing screens or irregularly shaped screens, transportation and installation are more difficult, requiring a professional team to operate.

Otherwise, project delays are likely. Advance planning is crucial to ensuring a smooth project launch.

3) How to find a balance between budget and needs

Not all projects require full customisation. The key is to first clarify the core needs: is it visual impact, brand display, or basic information dissemination?

Based on priority, allocate the budget to the parts that have the greatest impact on the effect, such as the core area of the screen or the position most easily noticed by the audience.

For the remaining parts, standard screens or reduced pixel density can be chosen.

This controls costs without affecting the overall experience.

4) Long-term investment vs. one-time expenditure

While customised screens require a large initial investment, for projects with long-term use, their brand value, user experience, and durability often bring returns.

Decision-makers need to weigh whether to pursue low one-time costs or invest in long-term investments to ensure the screen is stable and enhances the brand image in the long run.

Understanding this difference can help make more rational selection decisions.

4. Advantages of customised LED displays

1) Seamless Integration with Space, Enhancing Visual Impact

Customised screens can be designed in size and shape according to the spatial form, seamlessly integrating with the environment, whether it’s a curved wall, a column-wrapped surface, or an irregularly shaped wave screen.

For example, in the atrium of a high-end ショッピングモール, the design team used curved, small-pitch LEDs to create a wraparound screen, allowing customers to see the complete image from different angles.

The space was instantly illuminated, and the visual impact far exceeded that of ordinary rectangular screens.

Customised screens not only display information but also become part of the spatial design, making the overall effect more sophisticated and unified.

2) Supporting Corporate Marketing and Interactive Innovation

Customised screens can realise more creative gameplay and interactive functions.

例えば、 展示会 or brand events, companies can control the screen content through touch or motion sensing to achieve real-time interactive displays.

In large-scale outdoor advertising, irregularly shaped or wraparound screens can make advertising content more eye-catching and create an immersive experience.

Customised screens allow marketing activities to go beyond simply playing videos, enabling interaction with the audience, increasing engagement and reach.

3) Enhancing Customer Experience and Corporate Image for Differentiated Competition

Customised screens showcase unique content and immersive experiences, leading to a higher perceived brand value for customers.

For example, a corporate experience centre uses フレキシブルLEDディスプレイ to create a wave-shaped wall, displaying brand stories and product information, leaving a lasting impression on visitors.

Compared to standard screens, customised screens not only display content but also subtly enhance the corporate image, allowing the brand to stand out from the competition and providing customers with a more upscale and professional experience.

5. Special Customisation Risks and Precautions

Customised screens often involve curved, irregularly shaped, or large-scale splicing, which presents technical and construction challenges.

For example, when splicing curved screens, precise calculations of pixel spacing and module angles are required; otherwise, the image can easily become distorted.

Large screens may also involve issues related to support structure, load-bearing, heat dissipation, and power distribution.

If the construction team lacks experience, installation errors or later instability can easily occur.

While customised screens offer stunning effects, maintenance and upgrades may be more complex than with standard screens.

For example, unreasonable modularisation or custom-made components may lead to prolonged downtime for replacements in case of malfunctions.

Upgrading content or adding features can increase modification costs due to the screen’s unique shape.

Therefore, ease of maintenance and upgrades should be considered during the design phase.

When selecting a supplier, don’t just look at the price or demonstration effect. Focus on their technical capabilities, customisation experience, and the reliability of their successful cases.

Whether the supplier has experience with similar projects, can provide a complete solution (design, installation, commissioning, after-sales service).

And whether their cases have been running stably for a period of time are all important indicators of their capabilities.

Decision-makers can reduce risks in several ways: clearly define customisation goals and budgets in advance, assess construction and maintenance feasibility, select suppliers with mature experience.

And clearly define installation standards, acceptance requirements, and after-sales guarantees in the contract.

Especially for large or uniquely shaped screens, it’s best to verify design feasibility in advance with small-scale samples or simulations to avoid problems after project implementation.

6. 結論

Special spaces and creative requirements may complicate screen selection, but once the core principles are grasped, customised screens can be successfully implemented.

The key is to first clearly define your goals and the characteristics of the space, assess technical feasibility, budget, and maintenance difficulty, and then select an experienced supplier and a mature solution.

In this way, your LED screen will not only blend perfectly with the space, presenting a unique visual effect, but also ensure stability and long-term usability.

Finally, if you would like to learn more about LED displays, ご連絡ください。