Introduction

In daily life, we often ignore the importance of power cords, thinking that it is just a simple connection tool. But do you know that inferior power cords may bring huge risks to our equipment?

Especially for high-precision, high-energy Écrans LED, the safety hazards and performance problems that may be caused by inferior power cords must not be ignored!

Table des matières

1. Common characteristics of inferior power cords

1). Appearance characteristics:

The wire diameter is too thin: it looks as thin as a toothpick and can’t withstand high currents at all. This thin wire will heat up in a short time and may even burn out.

- Rough outer skin:

It feels like sandpaper and has a very poor feel. Moreover, the surface of the outer skin is bumpy, and there may be small holes in some places.

- Uneven colour:

The colour is dark and light, which makes it look very “copycat”. In some places, the colour fades so badly that you can even see the copper core inside.

- Blurred logo:

Either there is no word, or the word is unclear, and some don’t even have a brand. Regular power cords have clear logos, and inferior wires dare not write their “identity” clearly.

2). Internal structure problems:

- The copper core has many impurities:

The color is wrong, either black, white, or yellow. This copper core is very hard and has poor toughness. It may break if it is slightly bent.

- The insulation layer is thin:

It will break if it is pinched or torn, and it does not provide any protection at all. This thin insulation layer is easily broken by current and may leak electricity after long-term use.

Risk 1: Electrical performance risk

1). Unstable voltage

The copper core of inferior power cords is of poor quality and the wire diameter is very thin, just like a very thin water pipe, the resistance (resistance) when water (current) passes through is large.

When the resistance is large, the voltage will “power off” during the transmission process, resulting in unstable voltage received by the device.

1.1). Impact on LED screens:

- Brightness flickering:

If the voltage is unstable, the brightness of the LED screen will “jump”, just like a light bulb flickers, which is very uncomfortable to watch and easy to cause eye fatigue.

- Colour deviation:

The colour display of the LED screen requires a stable voltage. Voltage fluctuation will make the screen colour look inaccurate.

For example, red may be darker and blue may be grey, affecting the visual effect.

2). Insufficient current carrying capacity

The wire diameter of the inferior power cord is too thin, just like a small water pipe cannot pass enough water, and the current is difficult to pass smoothly.

Moreover, the copper core has many impurities, which will also increase the resistance and make the current “stuck”.

2.1). Possible consequences:

- Power supply overheating:

If the current carrying capacity is insufficient, the power cord will heat up, just like the poor water flow will cause the water pipe to heat up. Over time, the power cord may burn out or even cause a fire.

- Dommages au matériel :

The equipment needs enough current to work properly. If the power cord “holds back”, the equipment is prone to problems.

Such as the computer may frequently freeze and restart, or the hard disk, motherboard and other components may be burned out.

A poor-quality power cord is like a “thief”, stealing current and voltage, making the equipment unable to work properly.

It will not only make the screen flicker and the color inaccurate, but also may cause the power supply to overheat, damage the equipment, and even cause a fire.

Therefore, don’t buy cheap and low-quality power cords. It is more reliable to choose good quality ones!

Risk 2: Safety hazards

1). Short circuit risk

The insulation layer of low-quality power cords is of poor quality, just like wearing a torn piece of clothing.

It is easy to be scratched, worn, or cracked by itself over time. Once the insulation layer is broken, the wires inside will be exposed.

If you accidentally touch other metal objects, or the two wires “touch each other”, a short circuit will occur.

When a short circuit occurs, the current rushes very strongly at once, just like a flood breaking through a dam.

The circuit board of the LED screen cannot withstand such a large current, and it will be burned out all of a sudden. The screen may be black and can never be used again.

What’s more terrible is that a short circuit will also make the power cord heat up.

If the temperature is too high, it may ignite flammable objects around it, such as carpets and curtains, and even cause a fire, which will have serious consequences.

For example, on May 18, 2019, a giant LED advertising screen in Times Square, New York, suddenly caught fire while playing an advertisement.

The fire may have been caused by problems such as aging insulation, insufficient wire diameter, or poor material of the power cord, which can easily lead to a short circuit or overload, thus causing a fire.

Fortunately, the fire did not cause any casualties, and the building where the billboard was located was not damaged.

Firefighters unplugged the power supply of the billboard in time and controlled the fire.

2). Leakage risk

The insulation layer of low-quality power cords is very thin, or the quality is not good, just like a leaky bucket, and the current can easily “leak” out from it.

This kind of power cord will not be used for long before the insulation layer will crack or break. If the current leaks out, people will get electric shocks.

In mild cases, you may feel a slight shock and feel very painful; in severe cases, it may cause cardiac arrest or even endanger your life.

Moreover, leakage can also burn out the power module of the device. For example, the LED screen may fail or even be completely scrapped due to lack of stable power supply.

Risk 3: Impact on service life

1). Accelerated aging

Poor-quality power cords are easy to “break down” during use, especially in high temperature and high current environments.

Because their insulation layer is of poor quality and the materials used may not be very good, they are easy to soften and become brittle at high temperatures, just like plastic will crack after being exposed to the sun for a long time.

Moreover, when a high current passes through, the power cord itself will heat up, and the insulation layer of the poor-quality power cord cannot withstand this heat, which will accelerate ageing.

After ageing, the insulation layer of the power cord will become particularly fragile and may break at a touch.

The copper core inside will also be affected and will oxidize over time, just like iron rusting.

After copper oxidizes, it will turn into green copper rust, and the conductivity will deteriorate.

In this way, the resistance of the power cord will increase, it will be more difficult for the current to pass through, the voltage will become unstable, and the performance of the entire power cord will be greatly reduced.

2). Shortened equipment life

Because the performance of inferior power cords is unstable, the voltage and current often fluctuate, and it is difficult for the LED screen to work “comfortably”.

The electronic components of the screen need a stable power supply to work properly, but the current provided by the inferior power cord is sometimes large and sometimes small.

The voltage is also unstable, which puts the components of the screen in a “tense” state.

Over time, the backlight of the screen may flicker frequently, the color will become inaccurate, and even freezes and restarts may occur.

Moreover, after the power cord ages, the resistance increases, and the current will heat up when it passes, which will also increase the internal temperature of the screen.

The electronic components of the screen are most afraid of high temperature. Once the temperature is high, the life will be shortened.

Therefore, poor-quality power cords will not only cause frequent screen failures but also greatly shorten the life of the screen.

A screen that could have been used for several years may be scrapped in one or two years because of the use of poor-quality power cords.

Risk 4: Electromagnetic interference problem

1). Generation of electromagnetic interference

Poor-quality power cords have poor shielding, just like not wearing clothes properly. When the current runs inside, electromagnetic waves will “leak” out.

Good power cords have shielding layers that can “lock” electromagnetic waves inside and prevent them from running around.

But the shielding layer of poor-quality power cords is either very thin or simply absent, so electromagnetic waves can easily run out.

These electromagnetic waves will run around in the surrounding space and can affect surrounding electronic devices, such as computers, speakers, routers, etc.

2). Impact on LED screens

Electromagnetic interference can cause various problems on LED screens. The screen may have noise, just like snow on the screen, when the TV signal is not good, and the picture becomes blurry.

There may also be flickering, horizontal or vertical stripes, and the color may become abnormal.

This is because the signal of the screen is interfered by electromagnetic waves, and the data cannot be transmitted, so the picture is naturally messy.

3). Potential impact on surrounding electronic devices

In addition to the screen, other devices will also be affected. The speakers may make noise, the signal of the wireless router may become weak, and the computer may frequently disconnect, or the data cannot be transmitted.

This is because electromagnetic interference will interfere with the signal transmission of the device, making the device “lost”, and the data cannot be transmitted, or it is transmitted incorrectly.

In short, poor-quality power cords will mess up the surrounding electronic devices, the screen display will have problems, and other devices will also easily fail.

Risk 5: Environmental adaptability issues

1). Insufficient temperature resistance

Poor-quality power cords are easy to “fail” in high or low-temperature environments.

The materials they use are of poor quality and cannot withstand extreme temperatures.

For example, at high temperatures, the insulation layer of poor-quality power cords may soften, deform, or even start to smoke, just like plastic on a hot pot.

At low temperatures, the insulation layer will become particularly brittle and may crack at the touch.

This lack of temperature resistance has a great impact on both power cords and LED screens.

Power cords are prone to short circuits at high temperatures and break at low temperatures.

For LED screens, the degradation of power cord performance will lead to unstable voltage, and the screen may flicker, distort colours, or even go black.

Moreover, if the power cord is damaged at high temperatures, it may also cause a fire, which will have serious consequences.

2). Poor corrosion resistance

Poor-quality power cords also easily break in humid or chemically corrosive environments.

Their insulation layer is of poor quality, and they are not waterproof or moisture-proof, and they are easy to absorb water.

For example, in a humid basement or kitchen, the insulation layer of poor-quality power cords may be corroded by water vapour and will crack and break over time.

If there are chemicals around, such as detergents and disinfectants, these chemicals will also corrode the insulation layer, causing the power cord to break faster.

Poor corrosion resistance has a great impact on the life of the power cord and the safety of the equipment.

Once the insulation layer of the power cord is corroded, the copper core inside will be exposed, which makes it easy to short-circuit or leak electricity.

This will not only greatly shorten the life of the power cord but may also cause damage to the equipment and even the risk of electric shock.

For example, leakage may burn out the circuit board of the LED screen or cause people to get an electric shock accidentally.

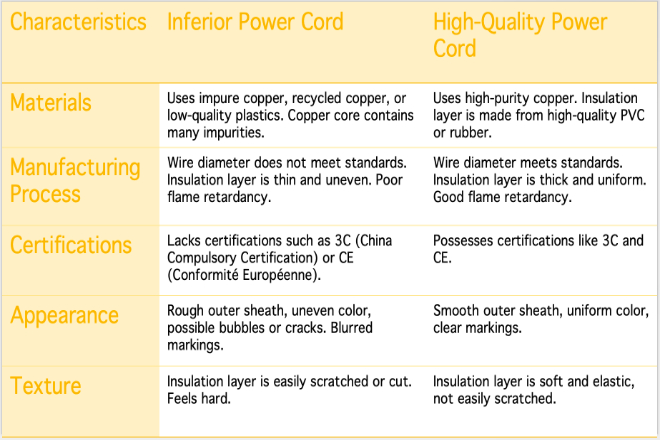

7. So, how can this kind of inferior power cord be avoided?

When buying a power cord, try to choose those big brands that everyone knows.

The quality of these brands of power cords is usually more reliable, because they will strictly control the production and will not easily let go of problematic products.

Although the products of big brands may be more expensive, they are safe to use, and will not have problems like some small workshop products after a short time.

When buying a power cord, be sure to check whether there are 3C certification or CE certification marks on it.

These marks are like the “certificate of conformity” of the power cord, indicating that it has undergone rigorous safety tests and is safer to use.

If there are no such marks, you have to be careful, maybe it is a low-quality product.

The appearance and feel of low-quality power cords are often not very good. A good power cord has a smooth outer skin, uniform color, clear writing on it, and will not fade easily.

If you see that the wire skin is rough, the colour is uneven, or the handwriting is blurred, it is likely to be inferior.

Touch it again. The insulation layer of a good power cord is soft and elastic, and it is not easy to cut off; the insulation layer of a low-quality power cord is hard, deformed by pinching, and easily damaged.

The quality of the wire diameter and copper core is also very important. A good power cord has a thicker wire diameter and will not be easily deformed by pinching.

A low-quality power cord has a very thin wire diameter and will be flattened by pinching.

Look at the copper core again. A good copper core is bright in color and has no impurities.

Alow-quality copper core is dark in color, and may be mixed with a lot of impurities, and has poor conductivity.

You must go to a regular place to buy a power cord, such as a large shopping mall, a speciality store or an official e-commerce platform.

The quality of the things in these places is guaranteed, and if there is a problem, you can find an after-sales service to solve it.

Never buy from roadside stalls or unknown small shops. The quality of the things in those places is not guaranteed, and you can’t find anyone if there is a problem.

Power cords that are too cheap are likely to cut corners in materials and workmanship.

Although they look cheap, they are not safe to use and may break down after a short time.

So, when buying a power cord, don’t just look at the price, but consider the quality and safety comprehensively. A slightly more expensive power cord is more reliable to use.

If you are not sure about the quality of the power cord, you can ask someone who knows the business around you, such as an electrician, a computer repairman, or a salesperson in the store.

They have a lot of experience and can help you distinguish the quality of the power cord and avoid buying inferior products.

8. Conclusion

The harm of inferior power cords to LED screens is far more than that. It not only affects the normal use of the equipment but also may endanger our safety. So, how can we avoid buying inferior power cords?

Choosing big brands, checking certification marks, and checking appearance and quality can all help us keep a good check. Remember, safety and quality are always more important than price!

Enfin, si vous souhaitez en savoir plus sur les écrans LED, merci de nous contacter.