Introduction

Have you ever encountered this situation: an écran LED extérieur, clearly labeled as waterproof, flickers or even shuts down in the rain?

Or seen a low-priced screen and thought it was “cost-effective,” only to have it break down soon after?

Actually, waterproofing is not as simple as looking at the surface numbers. Environment, design, materials, internal protection… every factor can affect the screen’s lifespan. So what are some common misconceptions?

And how should you choose and maintain a screen? Next, let’s talk about some common pitfalls regarding waterproofing outdoor LED displays.

Table des matières

Misconception 1: The higher the IP rating, the better

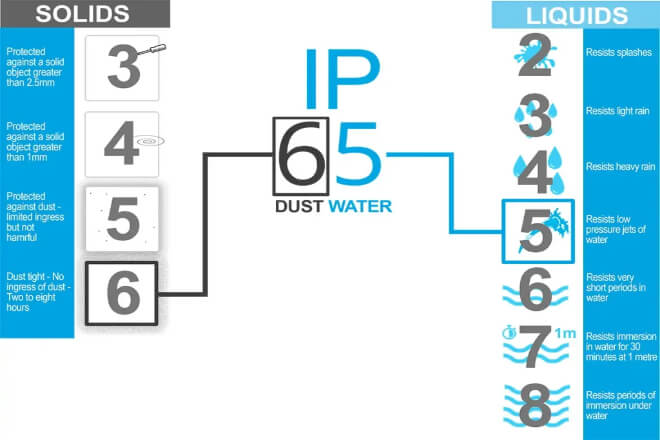

When choosing an outdoor LED display, many people’s first reaction upon seeing the IP rating is “the higher the better,” so they immediately focus on IP66 and IP67.

In fact, IP protection ratings are not for “comparing size,” but for different usage environments.

For example, IP65, IP66, and IP67 differ more in their waterproof testing methods than in which one is necessarily more durable.

For most urban outdoor scenarios, IP65 is perfectly adequate, handling normal rain and windy weather, and is currently the most widely used and mature solution.

Conversely, higher waterproof ratings and more sealed structures also increase the pressure on heat dissipation.

LED displays are devices that operate continuously with power; if heat cannot dissipate, the lifespan of the LEDs and the source de courant will be affected over time.

Furthermore, higher IP ratings often mean more complex structures and higher costs, but these investments may not be truly necessary in ordinary outdoor projects.

For example, IP67 is mainly for short-term immersion and does not necessarily mean it’s more suitable for long-term outdoor use.

Therefore, when choosing a waterproof rating, instead of blindly pursuing the “highest,” it’s better to choose one that is just right based on the actual environment. This is more cost-effective in terms of stability, cost, and lifespan.

Misconception 2: A Waterproof cabinet alone guarantees internal safety

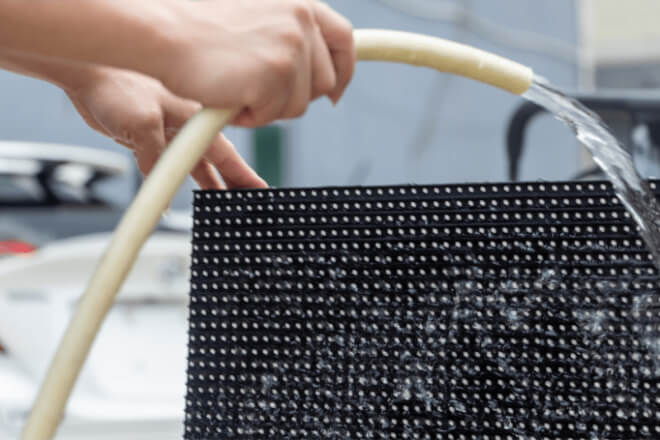

When purchasing outdoor LED displays, many people habitually only look at the waterproof rating of the cabinet.

Assuming that a sealed cabinet guarantees the safety of the internal modules, source de courant, and control system. This is actually a common misconception.

While the outer casing can indeed protect against rain and dust, internal circuitry and components can still become damp or infiltrated, especially under prolonged exposure to wind and rain.

The most common sites of internal leakage are often not the front glass, but rather interfaces, power cord connectors, control system ports, ventilation holes, and drainage holes in the enclosure.

If these areas lack adequate secondary protection, even if the enclosure itself meets IP65 or IP66 standards, water seepage through gaps or interfaces can lead to internal short circuits, component damage, or control system malfunctions.

The most common problems include screen flickering, uneven luminosité, power supply failure, and even complete screen shutdown. These faults are often more difficult to detect and repair than external leaks.

Therefore, a truly reliable waterproof solution for écrans LED extérieurs is more than just sealing the outer casing.

It requires a holistic protective design: including moisture-proofing measures for internal modules, waterproof power supplies, control system protection, drainage design, and sealing of critical interfaces.

Only in this way can the screen operate stably for extended periods under various weather conditions.

In other words, waterproofing is not just about protecting the outside; it’s a systemic project: the enclosure, internal modules, power supply, and control system must all be considered simultaneously; none can be neglected.

Understanding this is crucial for selecting a truly safe and reliable outdoor LED display screen when considering IP ratings and structural design.

Misconception 3: Waterproofing is Done After Installation

Many people believe that once an outdoor LED display screen is installed and tested, waterproofing is no longer an issue.

In reality, waterproofing isn’t a one-time fix; it requires long-term monitoring. The outdoor environment is complex and variable. Wind, rain, sun, and temperature fluctuations all affect the screen’s seal.

Over time, waterproofing materials and sealants will gradually age, shrink, and even crack. Screws and sealing rings at the interfaces may also loosen or shift.

Once these “hidden risks” materialize, rainwater and dust can seep in through gaps, causing malfunctions in the internal power supply, control system, or LED modules.

Often, this damage isn’t immediately apparent; the screen may only flicker occasionally or display abnormalities.

However, once problems accumulate, they can lead to widespread downtime or increased repair costs.

Therefore, waterproofing isn’t a one-time task after installation; it requires regular inspection and maintenance.

Key inspection points include ensuring interface sealing, unobstructed drainage holes, and the integrity of the cabinet’s protective layer, as well as replacing aged sealing materials when necessary.

Only proper long-term maintenance can ensure the stable operation of outdoor LED displays in various environments, truly achieving the intended effect of their waterproof rating.

Misconception 4: Waterproof Design Can Ignore Heat Dissipation

When purchasing outdoor LED displays, many people only focus on the waterproof rating, believing that a well-sealed screen is sufficient, neglecting heat dissipation.

In reality, waterproofing and heat dissipation are a crucial balance.

To improve waterproofing, the cabinet design is often more airtight. While this blocks rain and dust, it also restricts airflow.

If the heat dissipation design is inadequate, high-brightness screens operating for extended periods are prone to overheating.

Overheating not only affects display quality, such as reduced brightness and color deviation, but also accelerates the aging of Modules LED and power supplies, even leading to hardware damage or system malfunctions.

Especially in high-temperature, direct sunlight environments during summer, if the waterproof design completely ignores heat dissipation, the screen may malfunction within hours.

Often, these problems don’t manifest immediately but accumulate gradually, significantly shortening the screen’s lifespan.

Therefore, the design of outdoor LED displays cannot simply pursue waterproof ratings; heat dissipation performance must also be considered.

A reasonable heat dissipation solution includes natural convection within the cabinet, optimal layout of ventilation holes, and optimized power supply and module cooling.

If necessary, fans or thermally conductive materials can be used to assist cooling.

In short, only by finding a balance between waterproofing and heat dissipation can the display maintain stability and reliability under high brightness and long-term outdoor operation, truly realizing its value.

Misconception 5: Low price equals "high cost-performance ratio."

Many people’s first reaction when choosing écrans LED extérieurs is to look at the price, believing that cheap equals high cost-performance. However, this idea easily leads to pitfalls.

Low-priced screens often compromise on waterproofing materials and processes, such as using inferior sealants, rough interface treatment, and inadequate moisture protection for internal modules and power supplies.

Short-term use may be fine, but problems easily arise when exposed to heavy rain, humid environments.

Or prolonged high-luminosité operation—leaks, short circuits, control system malfunctions, or even complete screen shutdown.

Even more troublesome is that these “cheap” costs can easily turn into a series of hidden expenses later on.

Repair costs, downtime losses, and even the need to replace the entire screen often far exceed the initial cost of a slightly more expensive but reliable screen.

In other words, the money saved on a lower price may be entirely lost later.

Therefore, when choosing a screen, don’t just look at the price; consider the reliability of the materials and workmanship.

For example, the sealing of the cabinet and interfaces, the moisture-proof design of the internal modules, the aging resistance of the waterproof materials, and the manufacturer’s after-sales service and maintenance convenience.

A slightly more expensive screen with a reasonable design, good materials, and reliable after-sales service will ultimately be more worry-free and cost-effective in the long run.

Simply put, when buying an outdoor LED display, don’t just focus on the current price; consider the long-term cost to truly choose a good screen and avoid daily maintenance worries.

6. Correct Waterproofing Understanding and Selection Strategy

When purchasing an outdoor LED display, a correct understanding of the waterproofing concept and selection strategy is crucial.

First, match the IP rating and protection design to the specific usage environment.

Urban outdoor advertising screens are typically exposed to ordinary rain, wind, and sun, so IP65 is usually sufficient.

In coastal areas, dusty environments, or industrial settings, IP66 or enhanced protection in specific areas should be considered.

IP67 is only necessary for special scenarios where short-term flooding is possible. Blindly pursuing the highest rating not only increases costs but can also lead to heat dissipation problems.

Secondly, when choosing a supplier, don’t just look at advertised specifications; focus on real-world case studies and reliable test reports.

Waterproof designs validated by actual projects speak louder than simple IP numbers.

By reviewing the manufacturer’s success stories, on-site photos, or test videos, you can more intuitively judge the reliability of the waterproof design.

Waterproof design needs to cover the entire system, not just the enclosure. Internal modules, power supplies, control systems, interfaces, and other critical components must also be protected.

Details such as drainage hole design, sealant quality, and interface sealing can determine the screen’s long-term stable operation in windy and rainy weather.

Finally, waterproofing is not a one-time task; it requires ongoing maintenance. Regularly checking the integrity of interface seals, drainage holes for blockages.

And waterproofing materials for aging, as well as promptly cleaning internal dust and moisture, can significantly extend the screen’s lifespan.

Furthermore, understanding the manufacturer’s warranty policy and maintenance services is also crucial for ensuring the screen’s long-term reliable operation.

In summary, waterproofing outdoor LED displays is a systematic project: selecting an appropriate IP rating based on the environment, focusing on comprehensive system protection, choosing a reliable supplier, and ensuring long-term maintenance and warranty services.

Only in this way can the screen operate stably in various outdoor environments, without being disrupted by wind and rain.

7. Conclusion

Waterproofing is not a one-time task, but a systematic project from design to maintenance.

Understanding common misconceptions, choosing an appropriate IP rating, focusing on comprehensive system protection, and performing regular maintenance are all essential for the screen to withstand wind and rain and operate stably for a long time.

Doing it correctly not only saves time but also reduces hidden costs, which is true cost-effectiveness.

Finally, if you would like to learn more about LED displays, veuillez nous contacter.