介绍

In today’s digital age, the application scenarios for LED屏幕 are increasingly diverse. However, when businesses or individuals need custom LED screens in small quantities, they often face numerous challenges.

For example, how can a customised LED screen meet your needs while remaining cost-effective? How can you choose a reliable manufacturer and effectively communicate with them?

So, how can you address these issues?

目录

1. Clarify the purpose and application scenario; don't just order casually.

Don’t rush to place an order. LED screens aren’t universally applicable. Think carefully about the purpose and application scenario. Is it an exhibition, a window display, a conference room, or a store?

The requirements for each location are completely different: 展览 require high 亮度 and a large size that can be clearly seen from a distance.

Temporary structures must also be considered to be susceptible to collisions and dust.

Window displays may receive direct sunlight during the day, so the brightness must withstand it, but at night, it must be glaring, and the screen must be dust- and moisture-resistant.

Meeting rooms don’t need to be incredibly bright; the key is to be comfortable to look at. The size should be appropriate for the room size and seating distance; too large a size can overwhelm the space.

Stores, on the other hand, require long-term stable operation, energy efficiency, and a durable appearance. The size should not obstruct the merchandise or traffic flow.

Especially when purchasing in small quantities, you can’t set specifications haphazardly.

Every incorrect specification will lead to a complete rework process—returns, exchanges, shipping, reinstallation, and lost business—all of which are costs.

The safest approach is to first make a “small checklist”: usage time period, indoor and outdoor, viewing distance, installation dimensions.

Whether a protective grade is required, and take a few photos of the on-site lighting. This way, you’ll have minimal problems placing an order.

2. Customisation doesn't mean "unlimited." Understand which parameters can be modified.

Many people assume that customising an LED screen means “changing whatever you want.” This isn’t the case; customisation has its limits.

First, clarify which parameters are truly customizable: Common customizable parameters include size, 解决, structure, and packaging type, but the scope for manipulation varies for each.

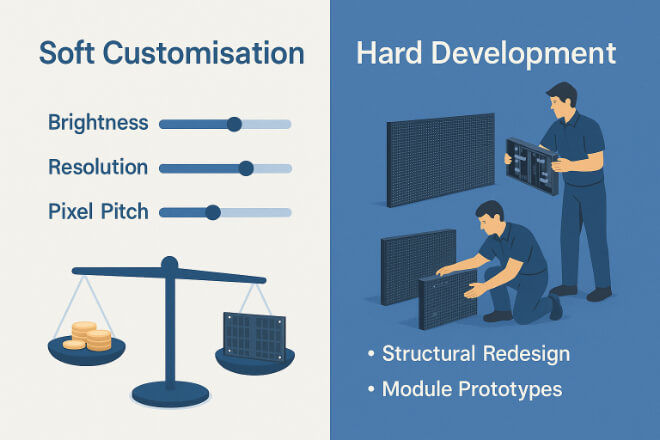

This can be categorised as “soft customisation” and “hard development.”

Soft customisation is more like building blocks, such as 亮度, 像素间距, and driver mode. You can easily adjust these settings to higher or lower settings.

Hard development is a completely different matter, requiring additional prototyping and even redesigning modules or protective structures. This leads to significantly higher costs and timelines than soft customisation.

Many people often mistake hard development for soft customisation, making unconventional requests right out of the gate. This not only doubles the budget but can also extend delivery times by weeks or even months.

To avoid pitfalls, it’s recommended to clearly outline your requirements before placing an order: which ones must be changed and which are simply parameters you wish to adjust.

Then, confirm with the manufacturer which constitutes soft customisation and which is hard development.

This ensures you receive an LED screen that truly meets your needs while also controlling costs and timelines, avoiding the embarrassing situation of “after spending so much time customizing, the screen still isn’t right.”

3. How to manage the cost risks of small-batch customisation?

Customising LED screens in small batches is like making your own clothes. While tailor-made is desirable, every stitch and every thread can cost money.

Prototyping fees, mould-making fees, and custom structural design fees are like the costs of cutting fabric, designing blueprints, and adding special materials. If you’re not careful, the cost per unit can skyrocket.

To save money, here are a few tips:

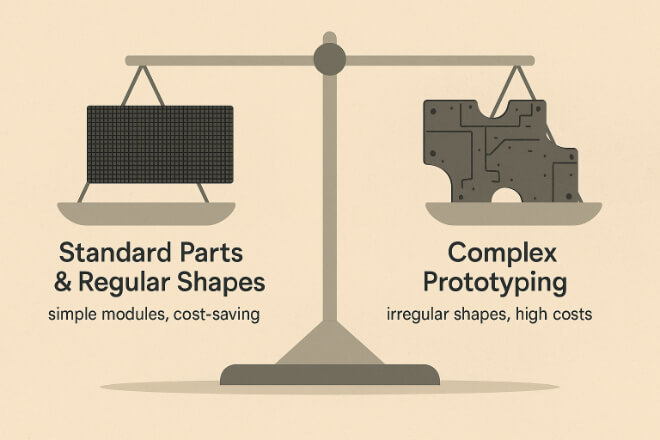

Try to use standard parts, just like using off-the-shelf fabric and zippers to tailor clothing—this saves both time and money.

Keep sizes consistent and avoid unusual shapes, which increase fabric costs and sewing complexity.

Minimise irregular shapes; a regular design is the most economical.

Another smart approach is “fine-tuning customisation,” which involves making small changes to existing modules, such as adjusting brightness, pixel pitch, or packaging, much like changing sleeve length.

Or collar shape on a ready-made garment. This approach can meet your needs without skyrocketing costs.

In short, small-batch customisation isn’t something you can just place a random order for.

Calculate every additional cost in advance and plan a reasonable fine-tuning plan to minimise cost risks and ensure you get a satisfactory LED screen.

4. Criteria for Choosing a Reliable Manufacturer

Choosing an LED screen manufacturer is like hiring a renovation team. It’s not just about the quote; it’s their expertise and experience that matter most.

Be sure to ask them if they’ve done small-batch work and if they can provide successful case studies. It’s like hiring a renovation team to renovate a small apartment.

Experienced ones know where to save money and time, and which pitfalls to avoid in advance.

Inexperienced ones, even if they offer a low price, may be slow and prone to problems, leaving you frustrated afterwards.

Secondly, it’s important to determine whether the factory is truly hands-on, capable of module design, structural modifications, and technical proofing, or whether they’re simply a broker for transferring orders.

A broker is like a middleman who helps you find a renovation team. They offer a low price, but if you run into problems.

You have to go to the construction site yourself, which not only wastes time but can also drive costs up dramatically.

A manufacturer with true development capabilities can quickly develop plans, produce proofs.

And conduct testing when faced with special requirements or last-minute adjustments, resulting in much higher efficiency and reliability.

Finally, it’s best to choose a manufacturer that offers a comprehensive service for proofing, testing, and mass production. This is like hiring a renovation team that oversees the entire process from design to construction.

Any problems can be identified and corrected promptly, resulting in a smoother final delivery.

This integrated service significantly reduces risk and saves time and effort, especially for small-batch customisation.

In short, when choosing a manufacturer, you shouldn’t just focus on price and promotional materials; their experience, development capabilities, and service system are crucial.

Choosing the right manufacturer will ensure your small-batch customisation is both efficient and worry-free, avoiding unnecessary hassles and potentially even surprises.

5. What details should be considered during the communication process?

Communication often determines the success of a customised LED screen. Many problems arise from not clarifying things up front.

First, preparation is crucial: prepare dimension drawings, on-site photos, and sketches of the finished product—the more detailed the better.

Just like planning room measurements, furniture placement, and desired effects before renovations, the manufacturer can accurately understand your ideas.

Minimising errors and preventing the finished product from differing significantly from your vision.

Furthermore, key requirements must be clearly stated, such as the installation method, power connector, and playback control method—all areas prone to problems.

Failure to address these requirements upfront can lead to the screen not fitting properly, the connectors not matching, or playback being awkward and difficult.

This is like discovering during renovations that the sockets are incorrect or the lights don’t fit properly—a series of small issues can become incredibly frustrating.

It’s best to make a list of all the details and confirm them with the manufacturer one by one, clearly highlighting the important requirements to avoid any omissions.

Finally, the confirmation process should be efficient. Use “video conferencing + sample confirmation” instead of repeated rework. Discuss ideas, revisions, and samples directly in front of you.

It’s like comparing design renderings online with a model apartment, allowing you to make changes. This is intuitive and convenient.

This not only saves time but also allows you to identify problems immediately, avoiding rework and unnecessary costs.

In short, the more detailed the communication, the smoother the customisation process: thorough preparation, clear requirements.

And efficient confirmation will ensure the screens are made exactly as you envisioned, saving time, worry, and a lot of hassle.

6. Conclusion

Small-batch customisation of LED screens is not difficult. The key lies in clarifying your requirements, planning appropriately, choosing the right manufacturer, and communicating effectively.

We hope the suggestions in this article will help you become more successful in customising LED screens and avoid unnecessary hassles and costs.

Finally, for more information about LED displays, please 联系我们。