介绍

在仓库管理中,效率和安全是永恒的追求,在复杂的环境下如何才能做到这两点呢?

单色LED显示屏或许就是你的秘密武器!那么,单色LED显示屏究竟如何在仓库管理中发挥如此多的作用呢?

目录

1、仓库使用单色LED显示屏有哪些优势?

在仓库里,单色LED显示屏就像一位“信息管家”。

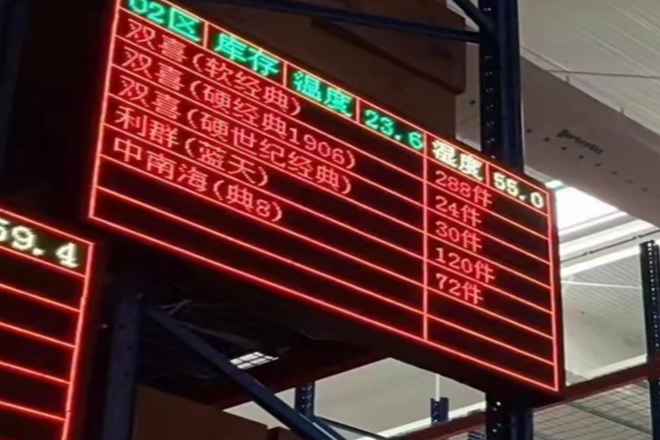

可以清晰的显示商品的货号、库存数量、摆放在哪个货架等各种信息。

比如你一眼就能看到“货号123,库存50件,在二楼5号货架”,找货的时候不用到处找,非常方便。

如果有易腐烂货物或危险品,它还可以提醒您“注意,该货物的保质期只剩3天”或“危险品,小心”,帮助您清晰地管理货物。

仓库里来来往往的车辆很多,物流运输特别繁忙。

单色LED显示屏在这个时候就可以发挥很大的作用了,在装卸区,它可以告诉装卸工人“货号456需要装卸,运往上海。”

预计30分钟内装好”,这样工人就不会装错货,发货也更快。

在仓库门口或者通道上,还可以给货车司机发出“A车,去1号装卸口”的指令,这样货车就不会乱开,仓库的交通也会更加顺畅。

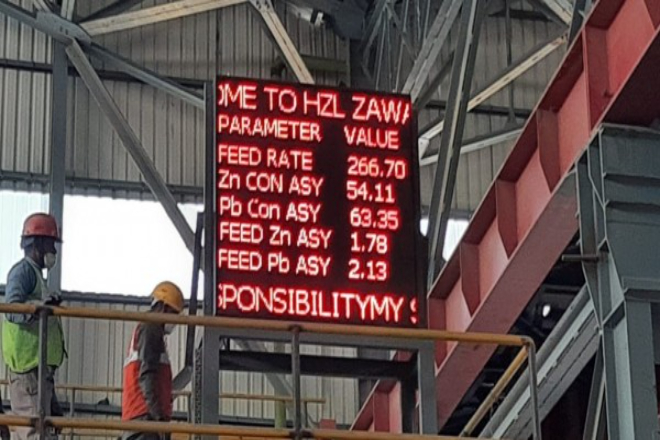

如果仓库中有叉车等物流车辆,显示屏还可以显示车辆的电量以及是否正常运行。

方便管理人员合理安排车辆,运输效率立竿见影。

仓库里安全是最重要的,单色LED显示屏就像一个“小安全卫士”。

在危险的地方或者重要的地方,它会提醒你“前面货物堆得有点高,请慢行”或者“这里是危险区域,必须佩戴安全设备才能进入”,这样就会减少事故的发生。

如果发生火灾等紧急情况,它可以告诉工作人员“往左边走,2号门是安全出口”,以便大家快速找到逃生路线,减少恐慌。

此外,它还可以帮助监视仓库中的设备。

如果设备出现问题,例如“789号设备,电机有点热,赶紧停机检查”,管理人员就能及时发现,确保仓库的安全运行。

仓库环境有时很恶劣;可能有灰尘、湿度和很大的温度变化。

单色LED显示屏特别耐用,不怕这些环境。

防水防尘,即使在露天仓库或靠近水的地方也能正常工作。

而且无论寒冷还是炎热的天气都能稳定显示,无需购买任何额外的设备来控制温度。

它的亮度也很高,即使仓库里的光线不是很好,也能看得很清楚。

最重要的是它非常节能,使用起来不需要花钱,可以帮助仓库节省大量的运营成本。

在仓库安装单色LED显示屏特别划算,结构简单,安装方便。

不需要复杂的线路和设备,因此安装成本很低。

它很少出故障。即使出故障,也很容易修理。只需更换一个小零件。维护成本很低。

使用寿命长,可以使用很多年,不需要频繁更换,长远来看,可以节省很多钱。

而且耗电量也比较低,能帮助仓库节省不少电费,真的是经济实惠又耐用。

单色LED显示屏使用起来特别方便,管理人员在办公室或者监控室,用电脑或者手机就可以进行远程操控。

想要改变显示的内容,只需要动动手指就可以了,不需要特意跑到现场去操作,省事。

此外,它还可以与仓库管理系统连接。

一旦货物入库或出库,就会自动更新显示的信息,例如库存数量。

所以不用担心手动操作失误,管理起来也更加容易。

总之,单色LED显示屏在仓库中非常好用。

它们可以帮助仓库管理货物,使物流运输顺畅,确保安全,并且耐用、节省成本、操作方便。

它们确实是仓库的好帮手。

2、单色LED显示屏在仓库管理信息显示中的应用

1). 存储位置信息显示

试想一下,仓库里摆满了密密麻麻的货架,堆满了货物,如果没有一个好帮手,找东西真的是一件很难的事情。

单色LED显示屏就像仓库里的“导航仪”,可以准确地告诉你每个存储位置的位置。

例如显示屏上会显示“这是A区第3排第4个货架”,这样工作人员就能快速找到目标存储位置,进货、取货都不再困难。

而且,这块显示屏还会实时更新存储位置的状态,如果货架还有空间,就会显示“空闲”;如果已满,就会显示“已占用”。

如果货架上有电子产品,也会标注“商品类型:电子产品”。这样,仓库里就不会出现货物杂乱堆放的情况。

2). 商品信息呈现

仓库里的货物种类繁多,每种货物都有自己的“身份证”,单色LED显示屏可以清晰地显示这些关键信息。

例如,显示屏上会显示“这是某品牌手机,64GB,共50台,5月10日入库”。

工作人员一抬头就能看到这些信息,不用再在箱子、柜子里寻找资料了。

对于一些特殊货物,比如易碎的玻璃制品或者需要冷链储存的食品,陈列上也会有特别的标记。

例如,“此为易碎品,请小心取拿”,或“此为冷链产品,温度必须保持在2℃”。

这样,工作人员在处理和储存这些特殊货物时就能更加小心,避免损坏或变质。

3). 工作指令的传达

仓库里有很多事情要做,比如拣货、搬运、上架等等,如果没有明确的指示,工作人员可能会很匆忙。

单色LED显示屏就像仓库里的“指挥官”,可以清楚地告诉工作人员该做什么。

例如,显示屏将显示“任务:拣货,货物编号12345,目标存储位置A3-4,数量10件”。

这样,工作人员就会知道自己要做什么、在哪里做、做多少。

此外,该显示屏还可以连接到仓库管理系统(WMS)。

一旦WMS系统有新的任务分配或者任务状态发生变化,显示屏就会立即更新。

例如,一旦系统分配了新的上架任务,显示屏就会立即显示新的任务内容。

这样工作人员就可以随时掌握最新的任务信息,快速、准确地开展工作。

单色LED显示屏在仓库中的作用不小。

它不仅可以帮助您快速找到存储位置,还可以清晰地显示货物信息,还可以指导工作人员完成各项工作。

3.单色LED显示屏用于仓库管理流程优化

1). 仓储流程优化

在仓库入库环节,单色LED显示屏就像一位“智能导游”,能起到很大的帮助作用。

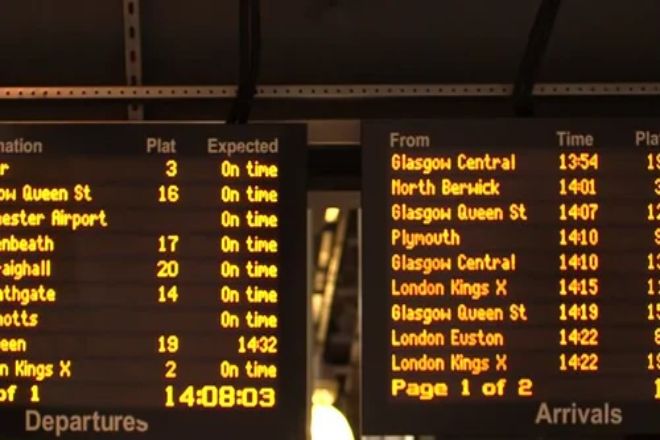

当满载的货车到达仓库门口时,显示屏会告诉司机“A车,请停在1号装卸口”。

这样,司机就可以快速找到停车位,而不必在仓库门口徘徊,节省大量时间。

货物开始卸货后,显示屏可实时显示货物的查验信息及存储位置。

例如显示“货号12345,检验通过,存放位置:B区第2排第5货架”。

这样仓库工作人员就可以快速的把货物放到指定的位置,入库速度一下子就提高了,而且货物也不会堆积在仓库门口。

2). 出库流程改进

出库的时候,单色LED显示屏也能发挥很大的作用,当有订单需要发货的时候,它会根据订单信息,快速定位货物的仓库位置。

例如显示屏上会显示“订单号56789,货物位置:C区第3排第4层货架”,工作人员可以快速找到该货物。

此外,显示屏还可以提供最佳的拣选路径引导。

例如会显示“先去C区第3排第4个货架取货,再去D区第5排第2个货架取货”。

这样工作人员就可以按照最短的路线去取货,避免很多不必要的弯路,自然就提高了工作效率。

在商品发出之前,显示屏上还会显示评价信息。

例如“订单号56789,商品数量:10件,已核实无误”,从而保证发货的准确性,降低发货的错误率,避免客户收错货。

3). 库存流程协助

盘点仓库货物是一项繁琐的工作,但单色 LED 显示屏可以使这个过程变得容易得多。

显示盘点任务及负责区域分配,如“盘点任务:第1排,A区,负责人:小张”。

这样,每个工作人员都知道自己需要盘点哪些货架,就不会出现重复盘点或漏盘的情况。

在盘点过程中,显示屏还可以实时反馈盘点进度及各项数据。

例如显示“A区第1行,盘点进度:50%,发现差异:品号12345,实际数量比系统数量少2个”。

这使得管理人员能够及时发现和处理差异,确保盘点结果的准确性。

单色LED显示屏确实是优化仓库管理流程的好帮手。

可以使入库、出库、盘点等流程更加顺畅高效,减少很多麻烦,让仓库的日常运营更加轻松。

4.单色LED显示屏在仓库人员管理与协作中的作用

1). 人员定位与调度

在仓库这样的大空间里,如果能随时知道每个工作人员的位置,管理起来就会方便很多。一块单色LED显示屏就能做到这一点。

可显示仓库工作人员的实时位置,如“小李在C区3排货架附近”。

这样管理人员就可以清楚的知道每个人在哪里,方便统一调度。

此外,显示器还可以根据每个人的工作量和位置智能地分配任务。

比如系统看到小李在C区办公,C区有紧急任务需要处理,显示屏就会提示他:“小李,C区第五排有紧急任务,请尽快过去。”

这样不仅可以提高工作效率,还可以让大家的工作量更加均衡,避免一部分人太忙,另一部分人无事可做。

2). 团队合作与沟通

仓库工作需要团队合作,信息共享非常重要。

单色LED显示屏就像一个“信息公告牌”,可以发布各种仓库管理规定和操作规程。

例如显示“操作流程:货物入库时,先检查外观,再扫码入库”。

让新员工可以快速上手,老员工可以随时复习。

当遇到紧急情况或者任务调整时,显示屏也能第一时间发出通知。

例如“紧急通知:D区发现漏水,请全体人员暂时避开该区域”或“临时任务调整:暂停原有的拣货任务,先处理A区的退货任务”。

这样,团队成员就可以及时调整工作计划,确保协作顺利进行,避免混乱。

5、单色LED显示屏在仓库数据分析和决策支持中的价值是什么?

1). 数据收集与整合

仓库每天都会产生大量的数据,比如货物的进出仓库时间、库存数量的变化、货物的丢失等。

单色LED显示屏就像一台“数据采集器”,它可以把仓库中各个作业环节的数据采集起来,并通过显示屏进行记录和传输。

例如,当货物入库时,显示屏上会记录“货物编号12345、入库时间:2025年5月15日、数量:100件”,这些数据会被整合到仓库管理系统中。

这样,单色LED显示屏还可以集成一些关键指标数据,例如库存周转率和货物丢失率。

库存周转率可显示“本月库存周转率:3次”,帮助管理层了解货物的流动速度。

货物损耗率可以显示“本月货物损耗率:2%”,让管理层可以清晰的看到损耗情况,这些数据的整合为后续的分析决策提供了依据。

2). 数据可视化

有了这些数据,单色LED显示屏也能直观地显示。

可以将数据分析结果以图表、曲线等形式展示出来,比如可以以柱状图的形式展示,比较不同商品的库存周转率。

或者用折线图来展示货物丢失率随时间的变化趋势,这样管理层可以快速洞察仓库的运营状况和潜在问题。

例如,显示“近三个月A商品的库存周转率持续下降”,管理层可以快速发现问题并采取措施。

这种直观的数据可视化方法使复杂的数字变得一目了然,帮助管理层更快地做出决策。

3). 决策支持功能

单色LED显示屏不仅可以显示数据,还可以提供决策支持,通过显示结果可以对数据分析给出一些针对性的建议。

例如,当库存周转率下降时,显示屏会提示“建议补货A,预计补货数量:50件”,帮助管理层及时调整库存。

并可模拟不同决策方案的实施效果。

例如,如果管理层考虑调整仓库布局,显示屏可以模拟“将物品 A 从区域 A 移动到区域 B。

预计可使货物周转率提高10%”,以便管理层在实施决策之前,清楚地了解可能产生的影响,从而做出最佳决策。

6、单色LED显示屏在多仓库管理中的扩展应用

1).分布式仓库信息同步

试想一下,一个公司有好几个仓库分布在不同的地方,管理起来一定很麻烦。

这时候单色LED显示屏就可以发挥很大的作用。

可以让不同仓库的显示屏“手拉手”,同步所有信息。

比如,总部的显示屏可以实时显示各分库房的库存情况,就像拥有了“千里眼”一样。

例如总部的屏幕上会显示“A仓库还有100件货物,B仓库还有80件”。

如果A仓库刚刚发出了10件货物,这个信息就可以立即同步到总部。

这样总部就可以根据各个仓库的情况,合理安排货物,而不用担心某个仓库缺货或者货物积压过多。

2). 供应链协同优化

单一彩色LED显示屏不仅可以帮助企业内部管理仓库,还可以与供应链中的“合作伙伴”(如供应商和物流公司)共享信息。

比如,当仓库里某种商品快卖完的时候,显示屏可以自动提醒供应商:“哎,货不多了,赶紧补货吧!”

这样,供应商就可以提前做好准备,不会延误供货。

与物流公司合作也比较方便。例如,您要将货物从A仓库调到B仓库,显示屏上会显示:

“物流任务:此批货物从A仓库运输至B仓库,预计明天上午10点到达。”

当物流公司看到这些信息后,就可以安排车辆和路线,确保货物准时送达。

这样,单色LED显示屏就如同连接仓库、供应商、物流公司的“信息助手”。

每个人都能及时看到库存周转速度、交货时间等关键信息,从而减少库存积压,降低物流成本,让整个供应链更加顺畅。

七、结论

通过本文的介绍我们可以看出单色LED显示屏在仓库管理中的应用远不止这些。

它不仅提高了货物管理的效率,而且可以优化物流运输、保证安全、降低成本,甚至在多仓库管理和供应链协同中发挥重要作用。

如果您还在为仓库管理的低效和复杂而烦恼,不妨尝试引入单色LED显示屏,为您的仓库管理注入科技力量。

最后,如果你想了解更多关于LED显示屏的信息, 请与我们联系。